Agitators Technology

Turbine Agitators

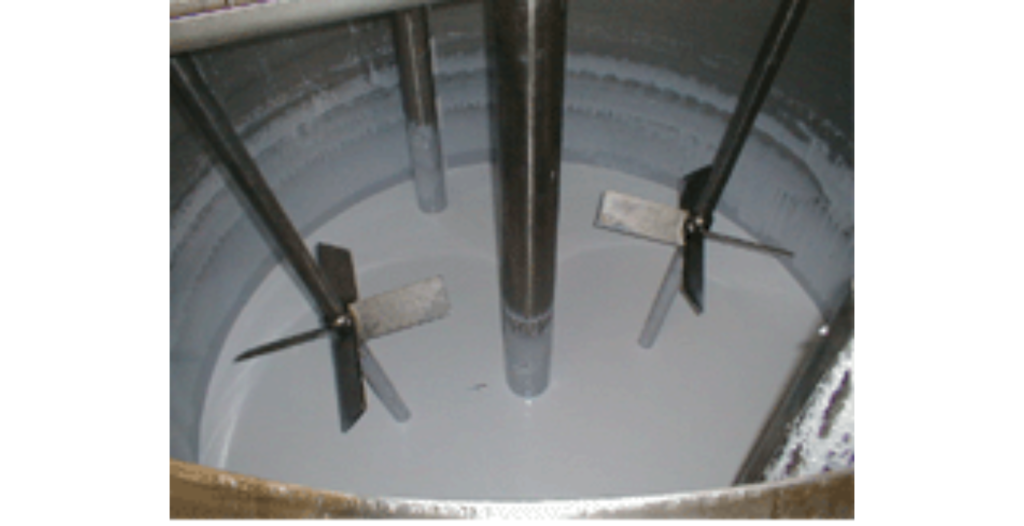

Turbine agitators, often referred to as axial flow agitators, are a type of industrial mixing equipment used to agitate and blend liquids in tanks or vessels. They are characterized by their distinctive impeller design, which resembles a turbine. The working principles of turbine agitators involve the following key aspects:

Design: Turbine agitators consist of an agitator shaft connected to a motor and an impeller with multiple blades. The impeller is typically positioned at the bottom of the tank or vessel.

Agitation: When the motor is activated, it drives the agitator shaft and impeller. The impeller’s rotation generates a vertical flow pattern, with fluid being drawn downward near the impeller and forced upward along the tank’s walls.

Flow Patterns: Turbine agitators create an axial flow pattern, characterized by the upward and downward movement of liquid along the agitator shaft. This flow pattern efficiently promotes mixing and circulation of the tank’s contents.

Speed and Direction: The speed and direction of the impeller’s rotation can be adjusted to control the mixing intensity and direction, allowing customization for specific applications.

Advantages:

Efficient Mixing: Turbine agitators provide efficient and effective mixing, ensuring uniformity and consistency of the liquid contents.

High Capacity: They are capable of handling large tank volumes, making them suitable for industrial-scale processes.

Customizable: Turbine agitators can be customized by selecting the appropriate impeller size, design, and speed to meet specific mixing requirements.

Low Energy Consumption: They often require less power compared to some other types of agitators, resulting in energy savings.

Versatility: Turbine agitators are versatile and suitable for a wide range of applications due to their efficient mixing capabilities.

Disadvantages:

Space Requirements: The design of turbine agitators can limit the usable space at the bottom of the tank, which may be a constraint in some applications.

Shear Sensitive: In some cases, turbine agitators may generate high shear forces, which can be detrimental to shear-sensitive materials or delicate biological processes.

Applications: Turbine agitators are used in various industries and applications, including:

Chemical processing: Mixing and blending of chemicals, polymers, and reactants.

Water and wastewater treatment: Agitation, flocculation, and chemical dosing.

Pharmaceutical manufacturing: Blending pharmaceutical ingredients, suspensions, and cultures.

Food and beverage production: Mixing ingredients in food and beverage processing, such as dairy and beverage mixing.

Pulp and paper: Stirring pulp stock in paper manufacturing.

Mineral processing: Agitating and suspending ores and minerals.

Summary: Turbine agitators are a type of industrial mixing equipment known for their efficient and effective mixing capabilities. They generate a vertical axial flow pattern, ensuring uniformity and consistency of the liquid contents in tanks or vessels. While they may have space limitations and the potential for shear-sensitive materials, turbine agitators are versatile and widely used in various industries for applications that require thorough mixing and circulation of liquids.

Sales & Marketing:

Sales & Marketing:  Service Supports:

Service Supports:  Website:

Website: