Pharmaceutical Technology/Products

Fluid Bed Dryer

Working Principles:

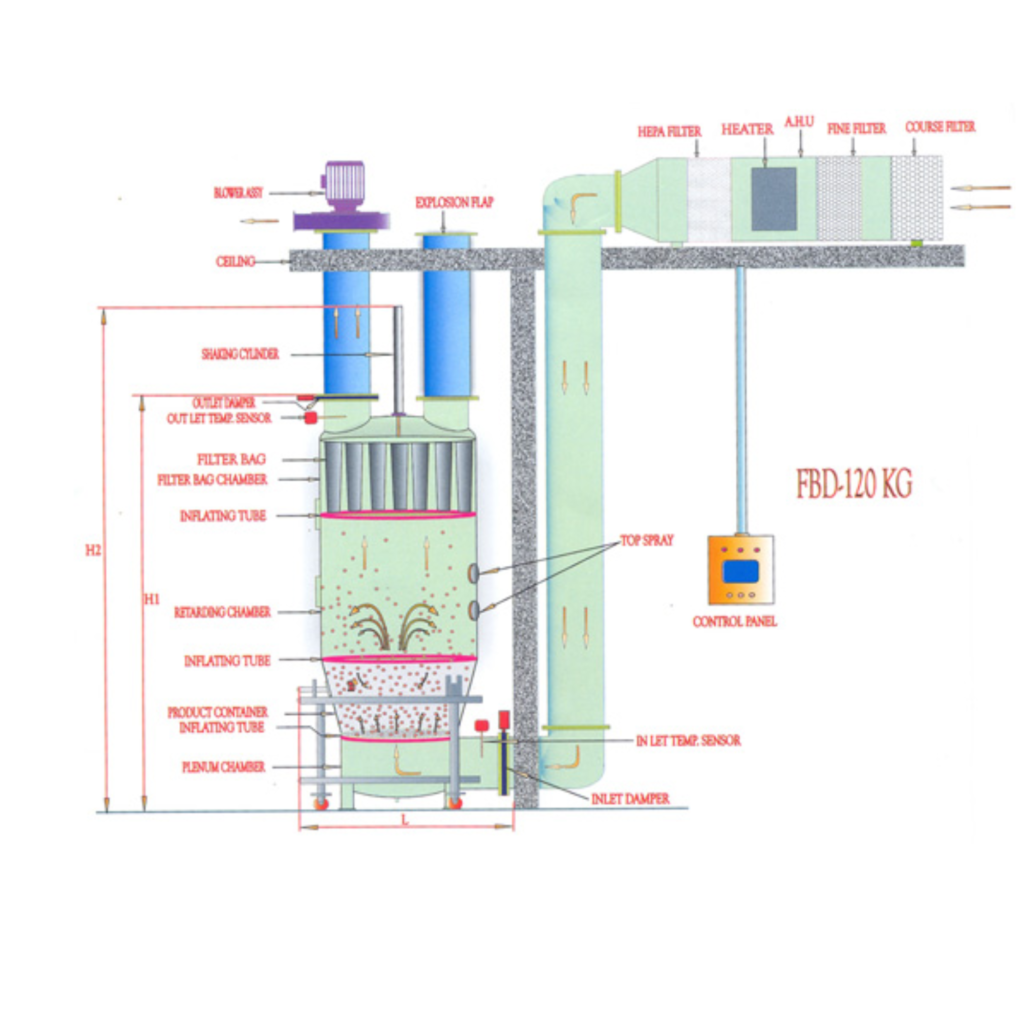

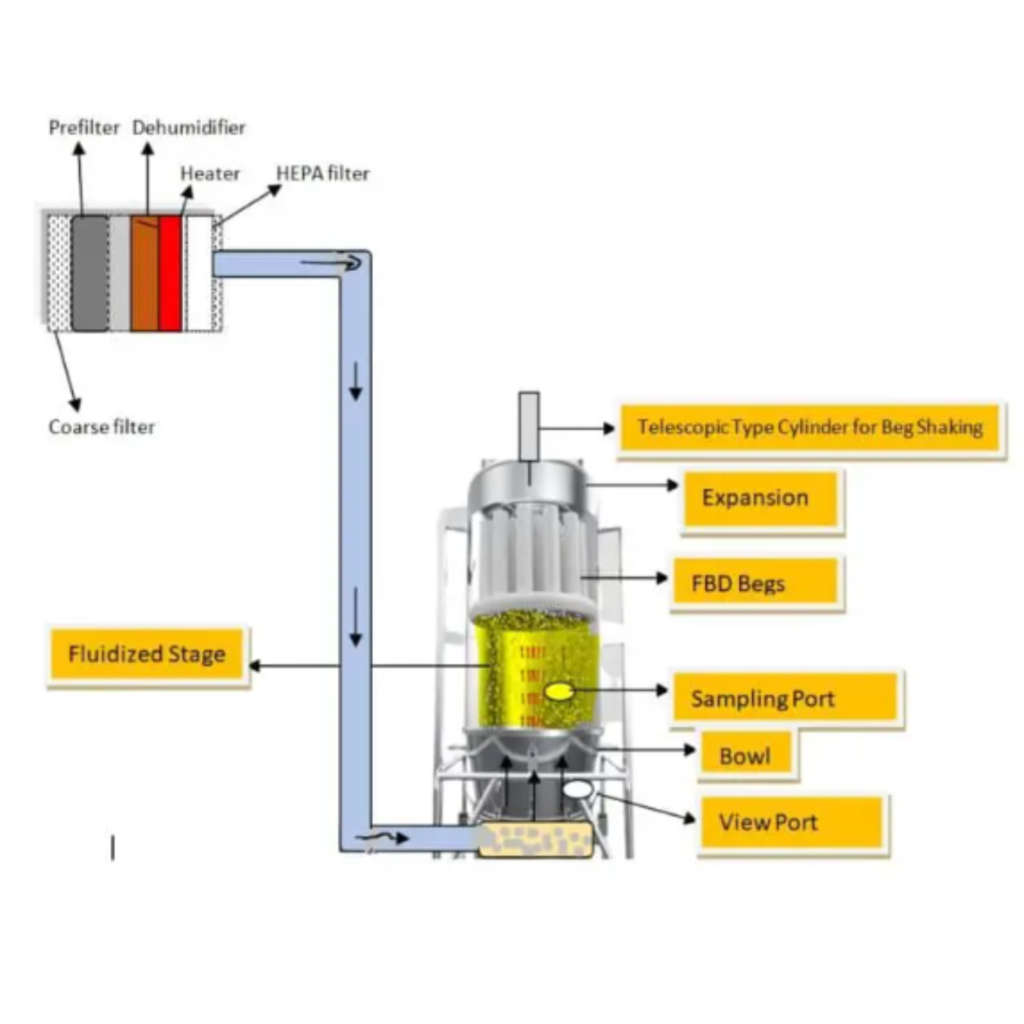

Fluid Bed Dryer (F.B.D.) is an industrial drying equipment, operates on the principle of fluidization using hot air, facilitating efficient and uniform drying.

The working principles of an FBD include:

Material Loading: The wet or moist material is loaded into the drying chamber, which consists of a perforated bed or container.

Fluidization: Heated air or gas is introduced from the bottom of the drying chamber through a distributor plate. The controlled airflow creates an upward force that suspends and fluidizes the solid particles within the bed.

Drying: The suspended solid particles are exposed to the hot air, which rapidly removes moisture or other volatile components. The constant movement within the fluidized bed ensures even drying.

Moisture Evaporation: Moisture or solvents evaporate from the particles and are carried away by the flowing air, maintaining a low-humidity environment within the dryer.

Product Cooling (optional): Some FBDs have a cooling zone where the dried material is cooled before discharge.

Product Discharge: Once the desired level of dryness is achieved, the dried material is discharged from the dryer for further processing or packaging.

Advantages:

Fast and Uniform Drying: FBD provide rapid and uniform drying, preventing agglomeration or clumping of particles.

Precise Control: Temperature, airflow, and residence time can be precisely controlled, ensuring consistent drying conditions.

Gentle Handling: They are suitable for heat-sensitive and thermolabile products due to the relatively low drying temperatures.

Energy Efficiency: FBDs are energy-efficient, as they use the latent heat of vaporization for drying.

Reduced Dust Emission: The fluidized bed minimizes dust emission, making them suitable for dusty materials.

Disadvantages:

High Initial Cost: The equipment cost for FBD can be relatively high.

Not Ideal for High-Moisture Materials: They may not be suitable for materials with extremely high moisture content or pasty materials.

Particle Attrition: In some cases, the constant agitation within the fluid bed can lead to particle attrition or breakage.

Applications: Fluid bed dryers are used in various industries and applications, including pharmaceuticals, chemicals, food processing, agriculture, cosmetics, minerals, and metallurgy.

Summary: Fluid Bed Dryer (FBD) is industrial drying equipment based on the principle of fluidization. They provide rapid and uniform drying, precise control over drying conditions, and are suitable for heat-sensitive materials.

However, they come with a relatively high initial cost and may not be ideal for very high-moisture materials or those prone to particle attrition.

FBD find application in pharmaceuticals, chemicals, food processing, agriculture, cosmetics, minerals, and metallurgy, making them a versatile and valuable tool for drying a variety of materials in different industries.

Sales & Marketing:

Sales & Marketing:  Service Supports:

Service Supports:  Website:

Website: