Textile Technology/Products

Hydro Extractor

Working Principles: Hydro extractor/centrifugal extractor/spin dryer is an industrial machine used to remove excess water/liquid from textiles, plastics & food products.

The working principles of a hydro extractor involve the following key aspects:

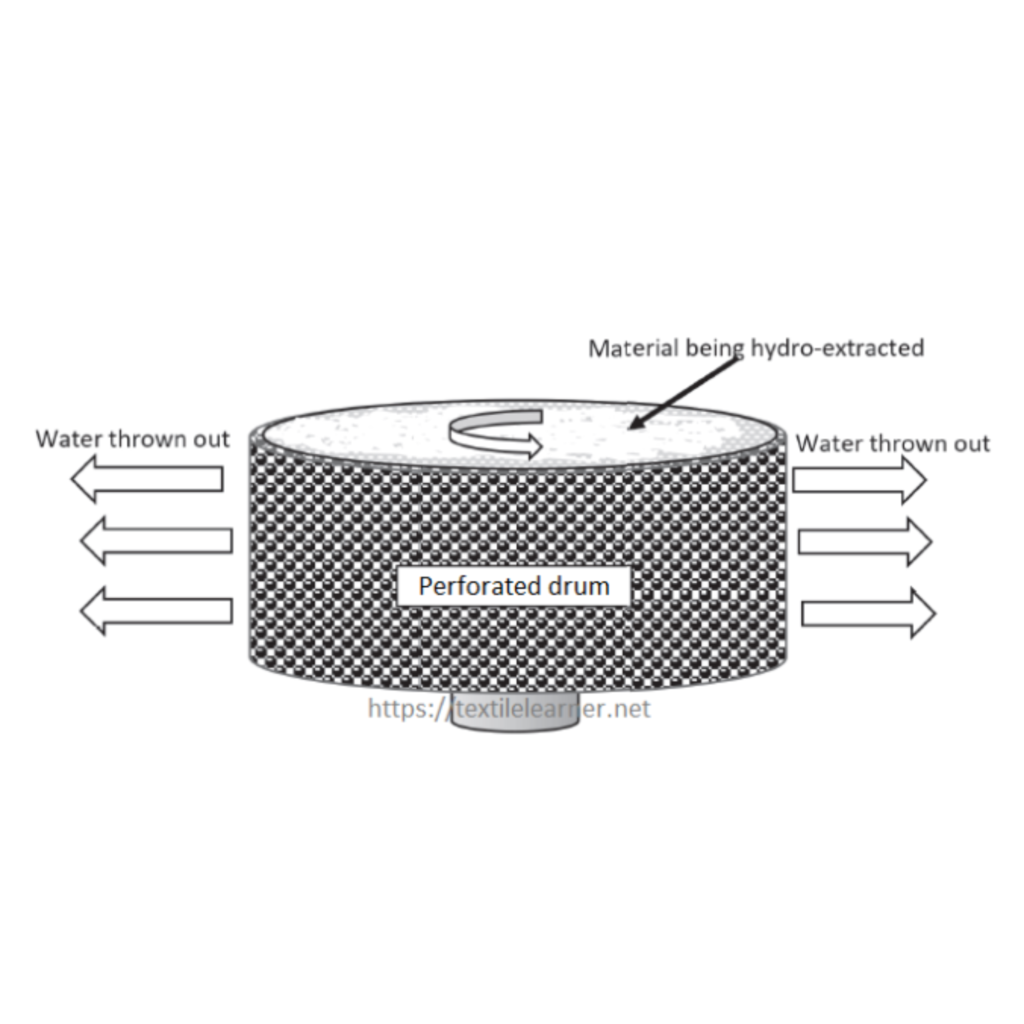

Design: A typical hydro extractor consists of a drum or basket-like container, usually made of stainless steel, mounted horizontally. The drum is perforated to allow liquids to pass through.

Loading: The material, such as wet textiles, is loaded into the drum. The load should be evenly distributed to prevent imbalance during operation.

Centrifugal Force: The drum is set in motion and rapidly spins, creating centrifugal force. This force pushes the liquid outwards, away from the center of the drum.

Drainage: As the drum spins, the liquid is forced through the perforations in the drum’s wall. It exits the drum and is collected in a separate container or drained away.

Balancing: To maintain stability and prevent excessive vibration, hydro extractors often include mechanisms to automatically balance the load during operation.

Control: Hydro extractors allow for precise control of spinning speed and duration to achieve the desired level of liquid removal.

Stopping and Unloading: Once the extraction process is complete, the spinning is stopped, and the material is unloaded from the drum.

Advantages:

Efficient Liquid Removal: Hydro extractors are highly effective at removing liquids from materials, significantly reducing drying times.

Energy Savings: By removing excess water before drying, hydro extractors help save energy during subsequent drying processes.

Faster Processing: They enable faster processing of materials, making them suitable for high-throughput operations.

Improved Product Quality: For textiles, removing excess water can improve fabric quality and reduce the risk of color bleeding.

Versatility: Hydro extractors can be used in various industries, including textiles, plastics, and food processing.

Disadvantages:

Mechanical Wear: The high-speed spinning and mechanical forces involved in hydro extraction can lead to wear and tear on the machine over time.

Maintenance: Regular maintenance is required to ensure the proper functioning of the machine and to address issues like unbalanced loads.

Applications: Hydro extractors find applications in a range of industries, including:

Textiles: Removing water from wet fabrics after washing, dyeing, or rinsing processes.

Plastics: Dewatering plastic pellets after the extrusion or washing process.

Food Processing: Removing excess liquids from fruits, vegetables, and other food products after washing.

Recycling: Dewatering materials like paper pulp and recycled plastics.

Metalworking: Dewatering metal chips and sludge from machining processes.

Summary: A hydro extractor is an industrial machine that uses centrifugal force to remove excess liquids from various materials.

It is known for its efficiency in liquid removal, which reduces drying times and saves energy.

Hydro extractors are versatile and find applications in industries such as textiles, plastics, food processing, and recycling.

While they offer significant advantages, they require regular maintenance to ensure their proper functioning.

Sales & Marketing:

Sales & Marketing:  Service Supports:

Service Supports:  Website:

Website: