Mixers/Blenders Technology/Products

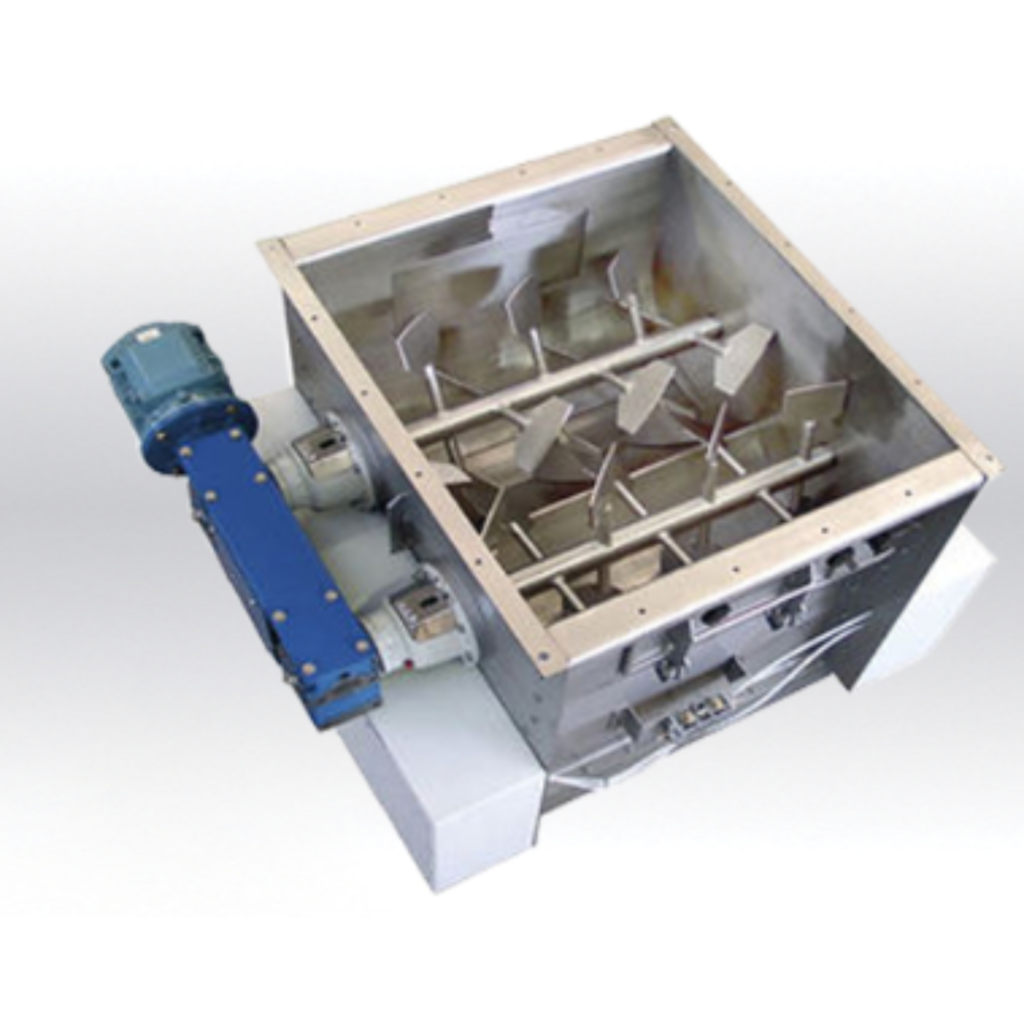

Paddle Mixers

Paddle mixers, also known as paddle blenders or paddle agitators, are common mixing devices used in blending technology to combine dry powders, granules, and other solid materials.

They are characterised by the presence of paddle-shaped mixing elements (blades) that are mounted on a horizontal shaft inside a trough or vessel.

Here’s an overview of their working principle, advantages, and disadvantages.

| Working Principle: The working principle of paddle mixers involves the rotation of paddle-shaped mixing elements within a horizontal or slightly inclined trough or vessel. The key working principles include: |

| Loading: The dry materials to be blended are loaded into the mixer through an opening at the top. |

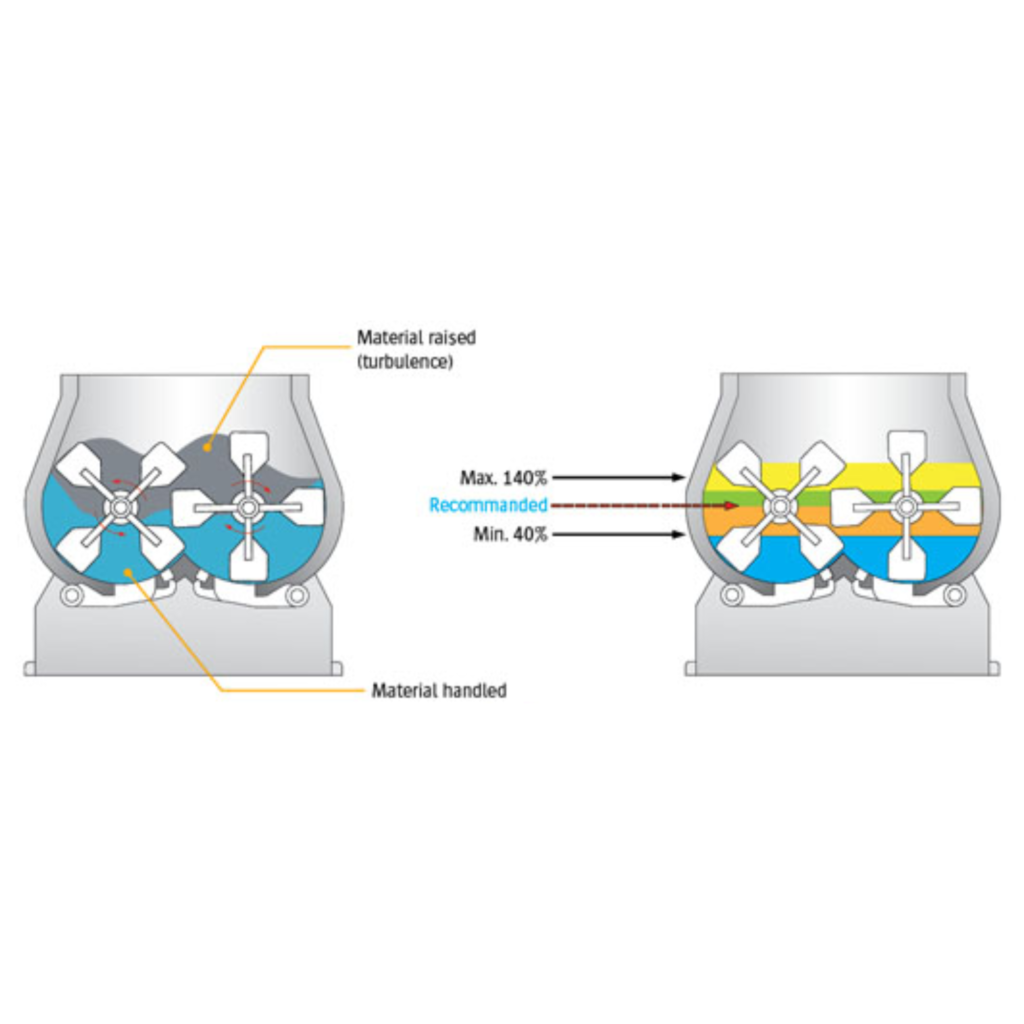

| Blending: Inside the mixer, paddle-shaped mixing elements are mounted on a horizontal shaft. These paddles rotate at a moderate speed within the trough. |

| Mixing: As the paddles rotate, they lift and gently tumble the materials in the trough. This action creates a rolling and cascading motion, ensuring that all components are mixed evenly. |

| Discharging: Once the blending process is complete, the blended mixture can be discharged through an outlet at the bottom of the trough. |

| Advantages of Paddle Mixers: |

| Uniform Mixing: Paddle mixers provide good mixing uniformity, ensuring that all components are evenly distributed throughout the mixture. |

| Versatility: They can handle a wide range of materials, including powders, granules, and materials with varying particle sizes. |

| Customization: The design and configuration of the paddles can be tailored to meet specific blending requirements, making them suitable for various applications. |

| Ease of Operation: Paddle mixers are relatively easy to operate and maintain, and many models offer variable speed controls for precise blending. |

| Efficient Mixing: They provide efficient blending within relatively short mixing times, reducing processing times and improving production efficiency. |

| Disadvantages of Paddle Mixers: |

| Batch Process: Paddle mixers are typically used for batch processing, which may not be ideal for continuous production lines. |

| Limited for High-Shear Mixing: While effective for many materials, paddle mixers may not be suitable for applications that require high-shear mixing or intense agitation. |

| Potential for Material Buildup: Some materials, especially cohesive or sticky substances, may adhere to the paddles or the trough walls, leading to material buildup and uneven mixing. |

| Limited for Temperature-Sensitive Materials: The mixing action can generate heat, which may be undesirable for temperature-sensitive materials. |

| Energy Consumption: Achieving the necessary rotation speed for efficient mixing can consume significant energy. |

In summary, paddle mixers are widely used mixing devices known for their versatility and ease of operation.

They are suitable for a wide range of applications that require efficient blending and moderate mixing intensity.

However, their batch processing nature and limitations in high-shear mixing may make them less suitable for certain production scenarios.

The choice of mixer type should be based on the specific characteristics of the materials and the blending requirements of the process.

Sales & Marketing:

Sales & Marketing:  Service Supports:

Service Supports:  Website:

Website: