BULK SOLID CONVEYING & GRAIN HANDLING SYSTEMS

Silo Storage Systems

Silo Storage Systems are essential components in various processing industries, especially in agriculture, food processing, and bulk material handling. They are used for the efficient and organized storage of bulk materials such as grains, cereals, cement, minerals, and other dry goods. Silos come in various shapes and sizes, and in this detailed overview, we will discuss the key aspects of silo storage systems, including equipment, working principles, advantages, disadvantages, applications, materials of construction (MOC), and provide a summary. |

| 1. Working Principles: Silo storage systems are designed to store bulk materials efficiently while ensuring their quality and ease of retrieval. The key working principles include: |

| Gravity Flow: Silos use gravity to feed materials downward, allowing for consistent and controlled discharge when needed. |

| Cone or Hopper Design: Silos typically have conical or hopper bottoms to promote material flow, preventing bridging and ensuring mass flow. |

| Aeration and Temperature Control: Some silos are equipped with aeration systems and temperature monitoring to prevent spoilage or clumping of materials. |

| 2. Equipment: Silo storage systems consist of several essential components: |

| Silo Structure: The main structure of the silo is typically made of concrete, steel, or other suitable materials. |

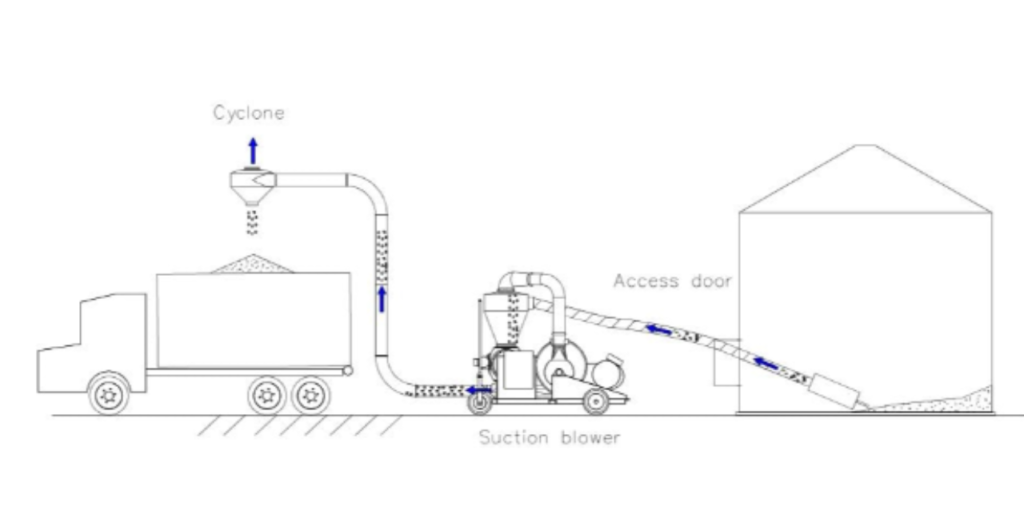

| Access Points: Silos have openings for filling and discharging materials. These can include hatches, spouts, and conveyor systems. |

| Aeration Systems: These systems introduce air into the stored material to prevent spoilage and promote even flow. |

| Temperature Monitoring: Sensors and control systems are used to monitor and control the temperature inside the silo to prevent moisture buildup and spoilage. |

| Conveyor Systems: Silos may be equipped with conveyor systems to transport materials in and out of the silo. |

| 3. Advantages: |

| Efficient storage and organization of bulk materials. |

| Prevention of material degradation, moisture, and contamination. |

| Space-saving design, allowing for vertical storage. |

| Easy automation and integration with material handling systems. |

| Suitable for a wide range of industries and materials. |

| 4. Disadvantages: |

| Initial setup costs for silo construction can be significant. |

| Maintenance and inspection are essential to prevent issues such as corrosion and leakage. |

| Material segregation can occur if not properly designed and maintained. |

| Limited access for cleaning and maintenance inside the silo. |

| 5. Applications: Silo storage systems have diverse applications across multiple industries, including: |

| Agriculture: Storing grains, seeds, and animal feed. |

| Food Processing: Storing and dispensing ingredients like flour, sugar, and spices. |

| Cement and Construction: Storing cement, sand, and aggregates. |

| Mining: Storing minerals, ores, and other bulk materials. |

| Chemicals: Storing and dispensing bulk chemicals and fertilizers. |

| 6. Materials of Construction (MOC): The choice of materials for silo construction depends on factors such as the type of material being stored and the environment. Common MOCs include: |

| Concrete: Durable and suitable for a wide range of materials, including grains and cement. |

| Steel: Provides strength and corrosion resistance, often used for corrosive materials like fertilizers. |

| Aluminum: Lightweight and corrosion-resistant, suitable for some food and chemical applications. |

| Plastics: Used for smaller, portable silos and materials that do not require heavy-duty storage. |

7. Summary: Silo storage systems are crucial in processing industries for the efficient storage of bulk materials. They rely on gravity flow and cone or hopper design principles, ensuring controlled and organized material discharge. These systems offer advantages such as material protection, space efficiency, and suitability for various industries. However, they come with initial setup costs, maintenance requirements, and limitations in terms of internal access. Silo storage finds applications in agriculture, food processing, construction, mining, and chemicals, with the choice of materials of construction tailored to the specific needs of the industry and materials being stored.

Sales & Marketing:

Sales & Marketing:  Service Supports:

Service Supports:  Website:

Website: