Centralized De-Dusting Systems

| Centralized De-Dusting Systems, also known as central dust collection systems, are essential components in processing industries that effectively remove airborne dust, particulate matter, and pollutants from multiple sources within a facility. These systems are designed to maintain clean air quality, protect worker health, and ensure compliance with environmental regulations. In this detailed overview, we will discuss the key aspects of centralized de-dusting systems, including equipment, working principles, advantages, disadvantages, applications, materials of construction (MOC), and provide a summary. |

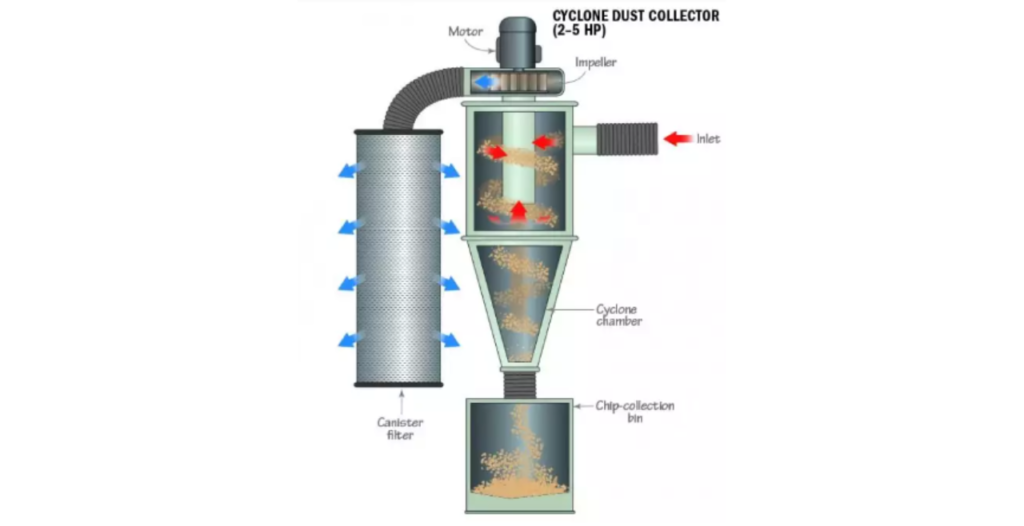

| 1. Working Principles: Centralized de-dusting systems operate on the principles of capturing, conveying, and collecting airborne dust and particulate matter from various production processes or equipment within a facility. The key working principles include: |

| Capture: Dust and particulates are captured at multiple source points using hoods, enclosures, or local exhaust ventilation. |

| Conveyance: Captured dust is transported through a network of ducts using fans or blowers, maintaining airflow velocity to prevent settling. |

| Filtration or Separation: The dust-laden air is passed through a central filtration or separation unit, typically consisting of filter bags, cartridge filters, or other media. This unit separates and collects the dust particles. |

| Cleaning: As dust accumulates on the filter media, it reduces airflow and filtration efficiency. Centralized de-dusting systems employ cleaning mechanisms such as pulse-jet cleaning or shaker mechanisms to dislodge and remove the collected dust. |

| Collection: The dislodged dust falls into a hopper or collection chamber, where it can be discharged for disposal or recycling. |

| 2. Equipment: Centralized de-dusting systems consist of several essential components and technologies: |

| Filter Bags or Cartridges: These are the primary filtration media that capture and retain dust particles. The choice of filter material depends on the application and the properties of the dust being collected. |

| Ductwork: A network of ducts, usually made of galvanized steel or other suitable materials, transports dust-laden air from source points to the central filtration or separation unit. |

| Fans or Blowers: These create the necessary airflow to move dust-laden air through the system. |

| Cleaning Mechanisms: Systems may employ pulse-jet cleaning, shaker mechanisms, or other techniques to clean the filter bags or cartridges. |

| Hoppers and Discharge Devices: Dust collected in the central unit falls into hoppers and can be discharged for disposal or recycling. |

| 3. Advantages: |

| Comprehensive Dust Control: Centralized systems effectively capture and control dust from multiple sources throughout the facility. |

| Improved Workplace Safety: Reduces the risk of dust-related health issues for workers. |

| Equipment Protection: Prevents damage to machinery and equipment caused by dust buildup. |

| Regulatory Compliance: Helps meet air quality regulations and emissions standards. |

| Energy Efficiency: Centralized systems can be more energy-efficient compared to multiple decentralized systems. |

| 4. Disadvantages: |

| Initial Setup Costs: The installation of a centralized de-dusting system can be expensive. |

| Maintenance Requirements: Filters and other components require regular maintenance and replacement. |

| Energy Consumption: Fans or blowers consume energy for operation. |

| Design and Layout Complexity: Proper design and layout are crucial for effective dust control. |

| Space Requirements: Requires space for ductwork and equipment placement. |

| 5. Applications: Centralized de-dusting systems are applied in various industries to control emissions, maintain air quality, and protect workers, including: |

| Manufacturing: Controlling dust generated by machining, grinding, and cutting operations. |

| Cement and Minerals: Reducing dust emissions from cement kilns and mining processes. |

| Woodworking: Collecting wood dust and sawdust in woodworking shops and mills. |

| Food and Beverage: Capturing flour, sugar, and food ingredient dust in processing facilities. |

| Pharmaceuticals: Controlling dust generated during drug manufacturing processes. |

| Chemicals: Capturing dust from chemical processing, mixing, and packaging operations. |

| 6. Materials of Construction (MOC): The choice of materials for centralized de-dusting systems depends on factors such as the type of dust, temperature, and corrosion resistance. Common MOCs include: |

| Galvanized Steel: Suitable for general industrial applications. |

| Stainless Steel: Used in food processing and corrosive environments. |

| Fiberglass Reinforced Plastic (FRP): Corrosion-resistant and lightweight, suitable for certain applications. |

| Special Coatings: Some components may have specialized coatings for increased durability. |

| 7. Summary: Centralized de-dusting systems are essential components in processing industries for comprehensive control of airborne dust and particulate matter. They operate on principles of capture, conveyance, filtration or separation, cleaning, and collection. These systems offer advantages such as comprehensive dust control, improved workplace safety, equipment protection, and regulatory compliance. However, they come with costs, maintenance requirements, and complexities in design and operation. Centralized de-dusting systems find applications in a wide range of industries, with the choice of materials of construction tailored to specific needs and environmental conditions. |

Sales & Marketing:

Sales & Marketing:  Service Supports:

Service Supports:  Website:

Website: