CONSTRUCTIONS TECHNOLOGY & PRODUCTS

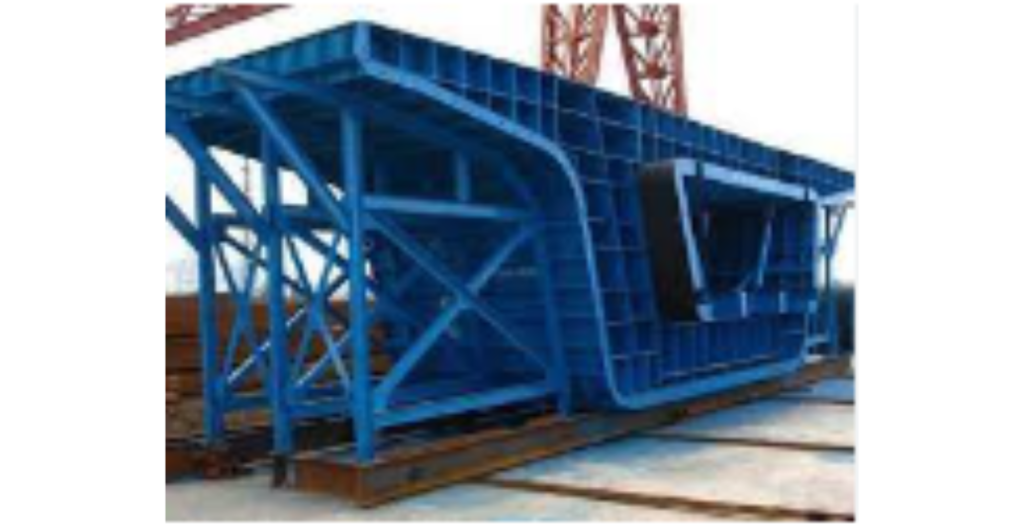

Formwork / Mold / Temporary Fabricated Structures

Formwork is a temporary structure or Mold used in construction to support and shape concrete or other construction materials until they are set or cured. It provides the necessary shape, alignment, and surface finish for concrete structures. In this detailed overview, we will discuss the key aspects of formwork, including its working principles, advantages, disadvantages, applications, materials of construction (MOC), and provide a summary. |

| 1. Working Principles: Formwork serves as a mold for concrete or other construction materials. The working principles of formwork include: |

| Support: Formwork provides structural support to the freshly poured concrete until it achieves sufficient strength to stand on its own. It must be designed to withstand the weight of the wet concrete and any additional loads. |

| Shape and Alignment: Formwork ensures that the concrete takes on the desired shape and alignment for the intended structure. It can be customized to create walls, columns, beams, slabs, and other structural elements. |

| Surface Finish: Formwork can also impart a specific finish to the concrete surface, such as a smooth or textured finish, depending on the type of formwork used. |

| Removal: Once the concrete has cured to the required strength, the formwork is removed carefully to reveal the finished concrete structure. |

| 2. Advantages: |

| Customization: Formwork allows for the creation of a wide range of shapes and sizes for concrete structures, accommodating architectural and engineering requirements. |

| Efficiency: It speeds up construction by facilitating the rapid placement of concrete, reducing labor and time. |

| Quality Control: Formwork ensures precision in construction, helping achieve accurate dimensions and surface finishes. |

| Cost-Effective: Properly designed formwork can be reused multiple times, reducing material and labor costs over multiple projects. |

| Safety: Formwork provides a safe working platform for construction workers during concrete placement. |

| 3. Disadvantages: |

| Cost of Fabrication: The initial cost of fabricating or purchasing formwork can be significant, especially for complex projects. |

| Labor-Intensive: Assembly, installation, and removal of formwork can be labor-intensive, impacting project schedules. |

| Maintenance: Formwork requires regular maintenance to ensure it remains in good condition and can be reused. |

| Environmental Impact: Disposable formwork materials can contribute to construction waste, whereas reusable formwork materials may have a higher environmental impact due to production. |

| 4. Applications: Formwork is used in various construction applications, including but not limited to: |

| Building Construction: For walls, columns, beams, slabs, and other structural elements in residential, commercial, and industrial buildings. |

| Bridge Construction: For bridge piers, abutments, and other concrete components. |

| Infrastructure Projects: In the construction of tunnels, dams, retaining walls, and water treatment plants. |

| Highway and Road Construction: For constructing curbs, barriers, and other concrete elements. |

| Specialized Structures: In the creation of structures with unique shapes or surface finishes, such as curved walls or decorative facades. |

| 5. Materials of Construction (MOC): The materials used for formwork can vary based on project requirements, but common materials include: |

| Timber: Traditional timber formwork is often used for smaller projects and is relatively cost-effective. |

| Plywood: Plywood is commonly used to face the formwork due to its smooth surface finish and durability. |

| Steel: Steel formwork is durable and can be reused multiple times. It is often used for larger and more complex projects. |

| Aluminum: Aluminum formwork is lightweight, corrosion-resistant, and can be reused, making it suitable for high-rise construction and mass housing projects. |

| 6. Summary: Formwork is a crucial component in the construction industry, serving as a mold for concrete or other construction materials. It supports, shapes, and aligns the material until it sets, allowing for the creation of a wide range of structures with precision and efficiency. Despite initial costs and labor-intensive aspects, formwork offers significant advantages, including customization, efficiency, quality control, cost-effectiveness, and safety. Formwork finds applications in various construction projects, and its choice of material, whether timber, plywood, steel, or aluminum, depends on project requirements. Proper design, installation, and maintenance are essential for successful formwork usage in construction. |

Sales & Marketing:

Sales & Marketing:  Service Supports:

Service Supports:  Website:

Website: