SYSTEM COMPONENTS & ACCESSORIES

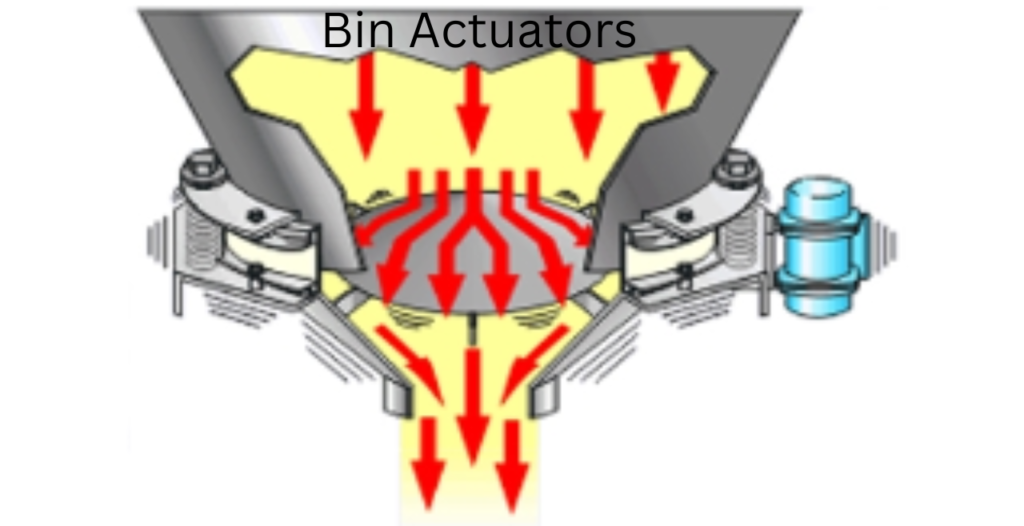

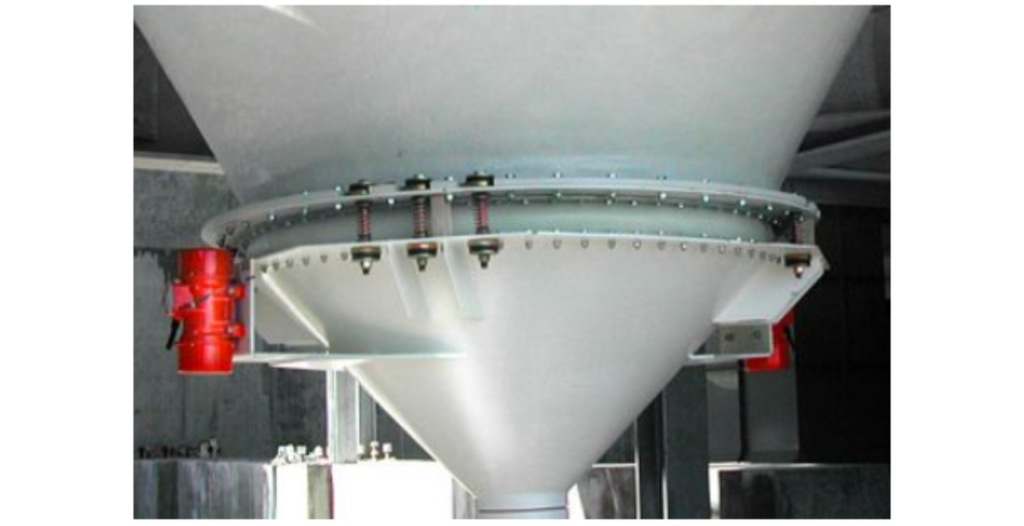

Bin Actuators/Bin Dischargers

Bin Actuators/Bin Dischargers are devices used in material handling and storage systems, particularly in bulk material storage bins and hoppers. They are designed to control the discharge of materials from these containers by regulating the flow rate.

Bin actuators play a crucial role in various industries, such as agriculture, mining, food processing, and manufacturing. Here’s a more detailed overview of bin actuators, including their working process, advantages, disadvantages, applications, materials of construction (MOC), and a summary:

Working Process: Bin Actuators/Bin Dischargers work by modulating the opening and closing of an outlet or discharge valve at the bottom of a storage bin or hopper. Their primary function is to regulate the flow of bulk materials, preventing overfilling or blockages. The working process can be summarized as follows:

Mounting: Bin Actuators/Bin Dischargers are typically mounted at the outlet or discharge point of a storage bin or hopper.

Material Flow Control: The actuator is equipped with a valve or gate that can be adjusted to control the size of the outlet opening. As the actuator is operated, it opens or closes the valve to regulate the flow of materials.

Control Mechanisms: Bin Actuators/Bin Dischargers can be manually operated, pneumatically operated, electrically operated, or controlled by a combination of these methods. The choice of control mechanism depends on the specific application and requirements.

Monitoring: Some Bin Actuators/Bin Dischargers are equipped with sensors or feedback mechanisms to monitor the flow rate and provide data for process control.

Advantages:

Flow Control: Bin Actuators/Bin Dischargers provide precise control over the discharge of bulk materials, ensuring a consistent and controlled flow rate.

Prevention of Blockages: By regulating material flow, they help prevent blockages and bridging in storage bins, which can disrupt operations.

Reduced Material Waste: Accurate control of material discharge reduces waste and spillage, leading to cost savings.

Automation: Bin Actuators/Bin Dischargers can be integrated into automated systems for improved process efficiency.

Disadvantages:

Cost: Bin Actuators/Bin Dischargers can be expensive to purchase, install, and maintain, especially for large-scale applications.

Complexity: Automated bin actuators may require skilled personnel for installation, programming, and maintenance.

Maintenance: Periodic maintenance is necessary to ensure proper functioning and to address wear and tear.

Applications: Bin actuators find applications in a wide range of industries, including:

- Agriculture: Controlling the discharge of grains, seeds, and feed in silos and grain bins.

- Mining: Regulating the flow of ores, coal, and minerals from storage bins.

- Food Processing: Managing the discharge of ingredients in food production processes.

- Manufacturing: Controlling the flow of raw materials or finished products in production lines.

- Chemical and Pharmaceutical Industries: Handling bulk chemicals, powders, and granules in storage vessels.

Materials of Construction (MOC): The choice of materials for Bin Actuators/Bin Discharger depends on factors such as the type of material being handled, the environmental conditions, and the desired service life. Common materials of construction include:

- Carbon Steel: Suitable for most industrial applications.

- Stainless Steel: Used in applications requiring corrosion resistance.

- Aluminum: Lightweight and corrosion-resistant, suitable for certain industries.

- Plastics: Used for specific applications where corrosion is not a concern.

Summary: Bin Actuators/Bin Dischargers are essential components in material handling and storage systems, providing precise control over the discharge of bulk materials from storage bins and hoppers.

They offer advantages such as flow control, prevention of blockages, reduced material waste, and the potential for automation. However, they can be costly and complex, requiring periodic maintenance.

Bin Actuators/Bin Dischargers have diverse applications across various industries and are typically constructed from materials selected based on the specific needs of the application.

Sales & Marketing:

Sales & Marketing:  Service Supports:

Service Supports:  Website:

Website: