Strainers

Strainers are a device or tool used for separating solid particles from a liquid or gas.

It is designed to allow the passage of the desired fluid while blocking or trapping larger particles or solids. Strainers are commonly used in various industries, including food and beverage, pharmaceuticals, chemical processing, water treatment, and many others.

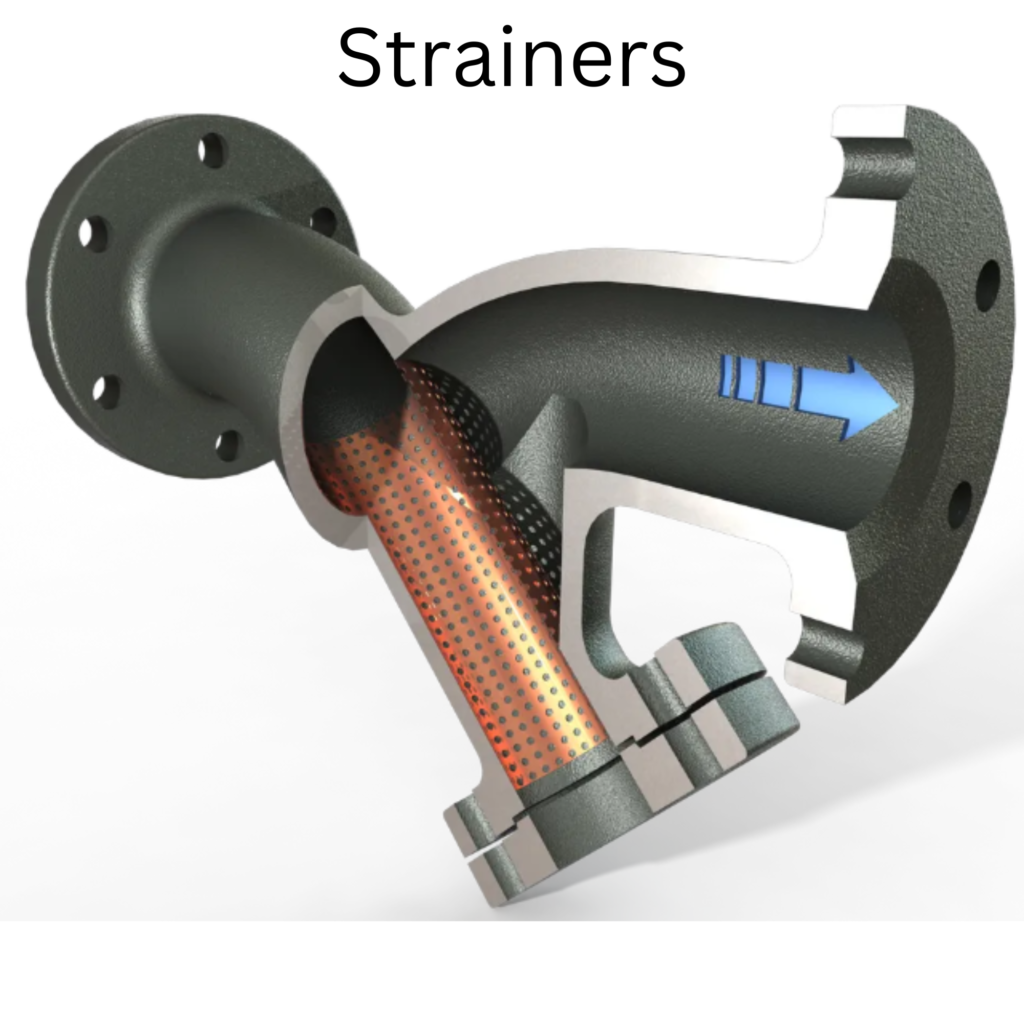

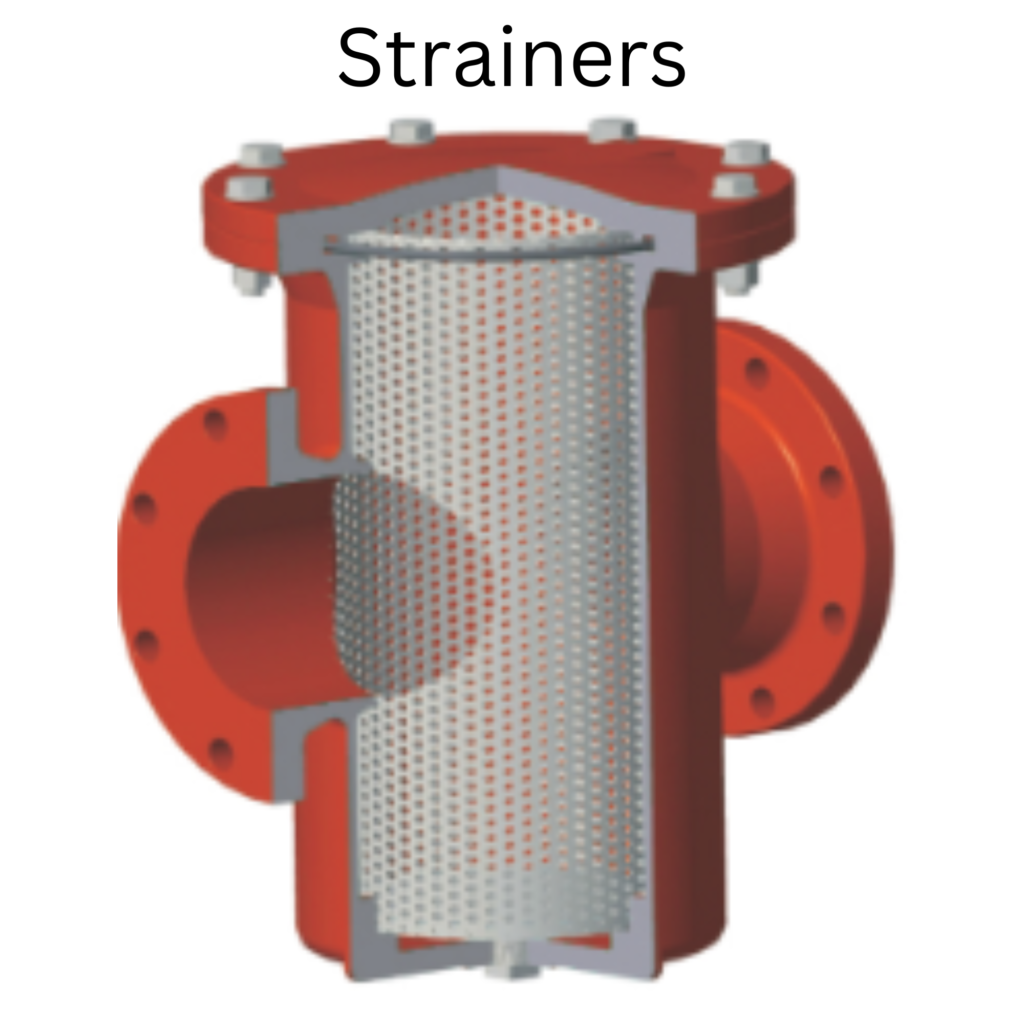

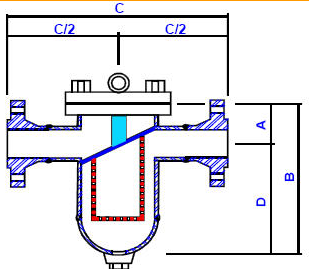

The basic design of a strainer typically consists of a mesh or perforated screen made of metal, plastic, or fabric. The fluid to be filtered is passed through the strainer, and the mesh or screen acts as a barrier, preventing larger particles from passing through. The filtered fluid then continues its flow, while the trapped particles remain in the strainer.

Overall, a strainer is a simple yet effective device used for filtration and separation purposes, ensuring the purity and quality of fluids in various settings.

Benefits & Silent Features:

- Particle Separation: The primary function of a strainer is to separate solid particles from fluids, ensuring the purity and quality of the liquid or gas. By capturing debris, sediment, or unwanted contaminants, strainers help prevent damage to equipment, improve product quality, and maintain process efficiency.

- Equipment Protection: By removing solid particles from the fluid, strainers help protect downstream equipment such as pumps, valves, nozzles, and heat exchangers. Strainers prevent clogging or fouling, which can lead to reduced equipment performance, increased maintenance costs, and potential system failures.

- Easy Maintenance: Strainers are designed for easy cleaning and maintenance. They can be quickly disassembled, allowing for the removal of trapped particles and debris. This convenience ensures minimal downtime during cleaning procedures, promoting efficient operation and reducing overall maintenance efforts.

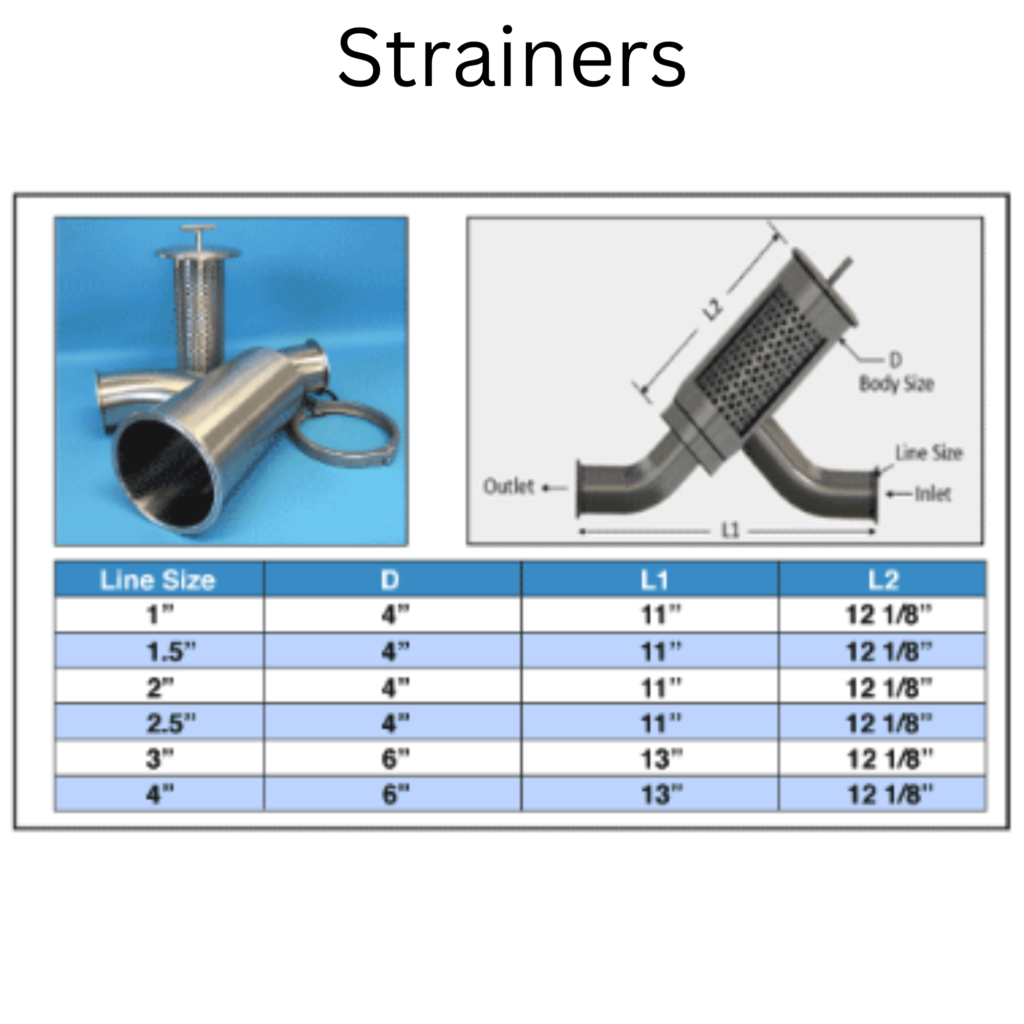

- Versatility: Strainers come in various sizes, configurations, and materials to accommodate different applications and fluid types. They can be customized to suit specific industry requirements, ensuring optimal filtration performance and compatibility with different fluids, temperatures, pressures, and corrosive environments.

- Pressure Drop Control: Strainers are designed to minimize pressure drop across the filtration system. They are engineered to have a low resistance to fluid flow while still effectively capturing particles. This feature helps maintain the desired flow rates and reduces energy consumption, ensuring efficient operation of the overall system.

- Scalability: Strainers can be easily scaled up or down based on the specific needs of a process or application. Whether it’s a small-scale residential strainer or a large industrial system, they can be tailored to accommodate different flow rates and particle sizes, providing flexibility and adaptability.

- Cost-Effective Solution: Implementing strainers as part of a filtration system can be a cost-effective solution compared to more complex filtration technologies. Strainers offer reliable particle separation at a relatively low cost, making them a practical choice for many industries.

In summary, the benefits and silent features of strainers include effective particle separation, equipment protection, easy maintenance, versatility, pressure drop control, scalability, and cost-effectiveness. These characteristics contribute to improved product quality, reduced equipment downtime, enhanced system efficiency, and overall operational reliability in a wide range of industrial applications.

Materials of Constructions (MOC):

- SA515 Gr.60

- SA516 Gr. 70

- IS2002

- IS2062,

- A106/ A53/IS1239/3589/ A105,

- ASTM A240 TP304

- ASTM A240 TP304-L

- ASTM A240 TP316

- ASTM A240 TP316-L

- A385/335/ A312TP 304/316

- A182/ F304 / 316/ F69 / F22/ F11

Applications:

- Water Treatment: Strainers play a crucial role in water treatment processes. They are used to remove suspended solids, sediment, and debris from water sources before further treatment steps such as disinfection, filtration, or purification. Strainers ensure the protection of downstream equipment and help maintain the quality of water for drinking, industrial processes, or irrigation.

- Food and Beverage Industry: Strainers are widely used in the food and beverage industry to separate solids from liquids and ensure product purity. They are employed in processes such as straining pulp from juices, removing seeds or skins from sauces, filtering cooking oils, straining particles from syrups or chocolate, and separating solid waste from wastewater in commercial kitchens.

- Chemical Processing: In chemical manufacturing and processing plants, strainers are utilized to filter out impurities and contaminants from liquids and gases. They help protect sensitive equipment, such as pumps, valves, and heat exchangers, from damage caused by particulate matter. Strainers are employed in processes like refining, petrochemical production, polymer production, and pharmaceutical manufacturing.

- Oil and Gas Industry: Strainers are essential components in the oil and gas industry for filtration purposes. They are used to remove solids, sand, debris, and other contaminants from crude oil, natural gas, and various fluids during extraction, refining, transportation, and distribution processes. Strainers help prevent equipment damage, and clogging of pipelines, and maintain the quality of the end product.

- HVAC Systems: Heating, ventilation, and air conditioning (HVAC) systems utilize strainers to protect components like chillers, pumps, and cooling towers from debris and particulate matter. Strainers in HVAC systems help maintain system efficiency, prevent clogging, and ensure the quality of the circulated air or cooling fluid.

- Power Generation: Strainers are employed in power plants, both thermal and nuclear, to remove impurities from water used for cooling systems, boiler feed water, and condensate. By capturing particles, strainers protect turbines, heat exchangers, and other critical components, ensuring the efficient and safe operation of power generation facilities.

- Pharmaceuticals and Biotechnology: In pharmaceutical manufacturing and biotechnology processes, strainers are used to filter out contaminants and particulate matter from liquids and gases. They help maintain the purity of raw materials, solvents, and process fluids, ensuring product quality and adherence to strict regulatory standards.

- Aquaculture and Fisheries: Strainers are employed in aquaculture and fisheries to separate solid waste, sediment, and debris from water sources in fish farms or fish processing facilities. They help maintain water quality, prevent clogging of filtration systems, and ensure a healthy environment for aquatic organisms.

T.E.A.M. offers Strainers ranging in any type of custom built from 15NB to 600NB.

T.E.A.M. Offers the specific application and selection of Strainers depending on factors such as the nature of the fluid, particle size, flow rates, operating conditions, and desired filtration efficiency. For any type of information, please feel free to contact us.

Sales & Marketing:

Sales & Marketing:  Service Supports:

Service Supports:  Website:

Website: