Evaporation Technology/Products

Forced Circulation Evaporator

Forced Circulation Evaporators are used in evaporation technology to concentrate liquid solutions with high viscosity or that contain heat-sensitive components.

FCEs are designed to facilitate the circulation of the liquid within the evaporator, ensuring efficient heat transfer and concentration. Here’s an overview of their working principles, advantages, and disadvantages

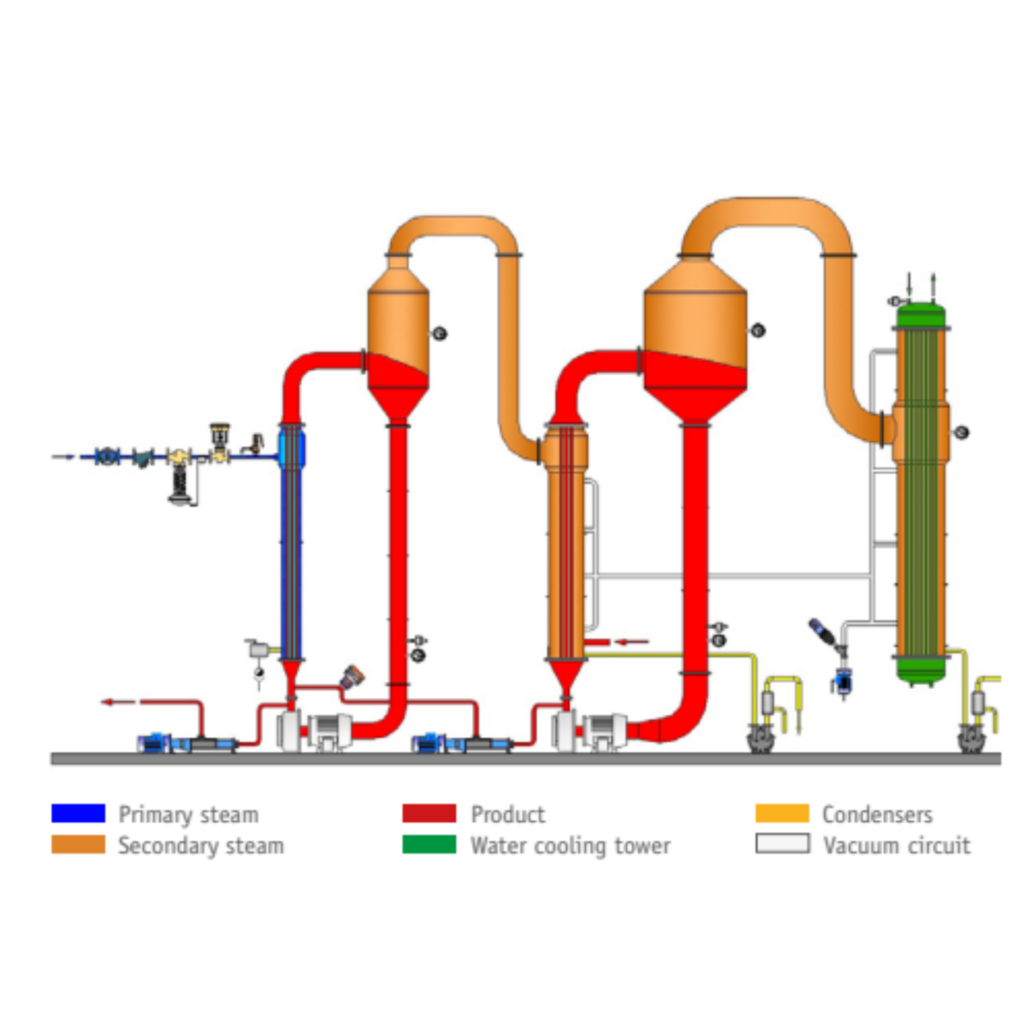

Working Principle: The working principle of a Forced Circulation Evaporator involves several key steps:

Feed Introduction: The liquid solution to be concentrated is introduced into the evaporator.

Circulation Pump: A circulation pump is used to continuously circulate the liquid within the evaporator. This circulation is important for maintaining a high velocity and preventing localized boiling.

Heat Transfer: A heating element, such as a steam jacket or an external heat exchanger, is used to provide heat to the liquid. The heat causes the solvent within the liquid to evaporate, leaving behind the concentrated product.

Vapor Separation: As the liquid circulates and absorbs heat, vapor is generated. A vapor-liquid separator is used to separate the vapor from the concentrated liquid. The vapor is typically condensed and collected for further use or disposal.

Concentration: The liquid in circulation becomes progressively more concentrated as solvent evaporates. The concentrated product is continuously removed from the evaporator.

Advantages of Forced Circulation Evaporators:

High Efficiency: FCEs are highly efficient due to the continuous circulation of the liquid, which ensures effective heat transfer and concentration.

Suitable for High Viscosity Liquids: They are particularly well-suited for liquids with high viscosity, as the circulation pump helps maintain flow even for viscous materials.

Gentle Processing: FCEs can be operated at relatively low temperatures under vacuum, making them suitable for heat-sensitive materials that might degrade at higher temperatures.

Continuous Operation: They are often designed for continuous processing, making them suitable for industrial-scale production.

Precise Control: FCEs offer precise control over the concentration of the final product, making them suitable for applications requiring specific concentration levels.

Disadvantages of Forced Circulation Evaporators:

Initial Cost: The equipment cost for FCEs can be relatively high compared to simpler evaporators.

Complex Design: FCEs have a complex design with circulation pumps and associated equipment, which may require more maintenance and cleaning.

Energy Consumption: Operating FCEs may require significant energy input, especially for the circulation pump and heating systems.

Not Suitable for All Liquids: While suitable for many applications, FCEs may not be the best choice for liquids that do not require forced circulation or for materials with a high solid content.

In summary, Forced Circulation Evaporators are efficient and versatile pieces of equipment used for concentrating liquid solutions, especially those with high viscosity or heat-sensitive components.

Their ability to operate continuously and their gentle processing make them valuable in various industrial applications. However, their initial cost, complexity, and energy consumption should be considered when selecting them for a specific application.

Sales & Marketing:

Sales & Marketing:  Service Supports:

Service Supports:  Website:

Website: