Paste Filter

T.E.A.M. Paste Filters

T.E.A.M. PASTE FILTERS:

In process equipment, systems & application, a Paste filter is a type of filtration system specifically designed to handle pasty or viscous materials.

It is used to separate solids from liquids or to recover valuable solids from a slurry or paste-like mixture.

The Paste filter is typically composed of a filtering medium, such as a filter cloth or a porous plate, which allows the liquid component to pass through while retaining the solid particles.

The paste material is usually fed into the filter by gravity or with the assistance of a pump, and pressure may be applied to enhance the filtration process.

The design of a paste filter takes into consideration the unique characteristics of the material being processed.

Pasty materials often present challenges to infiltration due to their high viscosity, tendency to clog filter media, and low filtration rates. To overcome these challenges, paste filters may incorporate specialised features, such as:

- Enhanced filtration area: Paste filters typically have a larger surface area for filtration compared to standard filters. This design allows for increased throughput and better separation efficiency.

- Pre-treatment or conditioning: Some paste materials require pre-treatment or conditioning to improve their filtration properties. This can involve adding flocculants or other chemical agents to aid in the formation of larger particle agglomerates, which are easier to separate from the liquid phase.

- Cake washing or dewatering: After the filtration process, the retained solid particles, known as the filter cake, may undergo additional washing or dewatering steps to further remove liquid and improve the quality of the separated solids.

- Automatic cake discharge: To facilitate continuous operation, paste filters may include mechanisms for automatic cake discharge. This can involve the use of scraper blades, vacuum systems, or other methods to remove the filter cake from the filter medium.

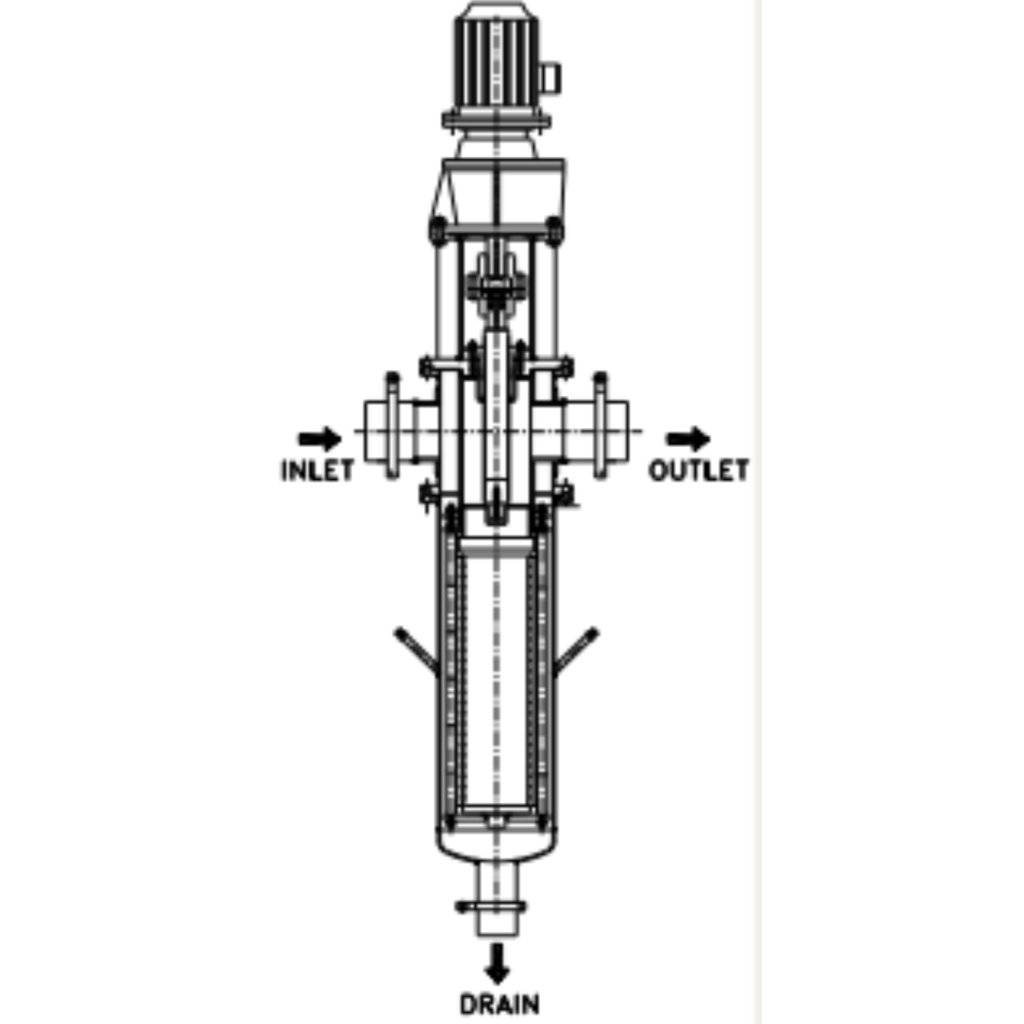

The Paste Filter consists of mainly four parts:

- Drive Assembly having Gearbox & Motor

- Intermediate Assembly having a rotating blade

- Filter Element (special type based on process)

- Filter Housing Drive Assembly (Pressure Vessel)

- Paste Filter is ideally suited for filtration of highly viscous or pasty fluids as solids are removed by scrapping in this filter.

- Compact in size

- Cleaning with special Scraper Blades

- Filter can be the jacketed type for heating with hot water, oil or steam.

- In-line installation, inlet, and outlet in the same axis of the equipment

- Using a special type of Non-clogging type metallic wedge wire filter element

- Non-metallic scrapers based on process

- Lightweight housing using trolley – easy for maintenance

- Fine filtration from 200 microns and above

- Fixed-type scraper

- Rotating element.

Materials of Constructions (MOC):

- MS

- CS

- SS304

- SS304L

- SS316

- SS316L

- Blade shall be in PTFE

- Tooth Paste

- Colour industries

- Lacquers

- Gums & Glues

- Emulsions

- Grease

- Dispersions

- Pastes & Syrups

- Shaving Cream

- Jelly Products

These are just a few examples of the wide-ranging applications where Paste filters are utilized to maintain efficient and continuous filtration in various industries and processes.

T.E.A.M. offers Paste Filters ranging from 200 microns & above.

T.E.A.M. offers a Paste filter with a customized design that best suits your process exhaust and fulfills the requirements. These are equipped with the latest design and features with automation, semi-automation & manual which allows for easy cleaning and ensures long-lasting operations. For any type of information, please feel free to contact us.

Sales & Marketing:

Sales & Marketing:  Service Supports:

Service Supports:  Website:

Website: