MIXERS/BLENDERS TECHNOLOGY & PRODUCTS

The term “Mixer cum Mixing Technology” refers to a combination of a mixer or mixing device and the associated technology used to achieve mixing and blending of materials.

This concept involves both the equipment used for mixing and the underlying principles, techniques, and technologies employed to efficiently and effectively combine different substances or components.

Mixers are mechanical devices or equipment designed to homogenize or combine different materials, such as liquids, powders, or gases. They are used in a wide range of industries and applications, including chemical processing, food and beverage production, pharmaceutical manufacturing, and more. Mixing technology encompasses the knowledge and methods used to optimize the mixing process, taking into account factors like material properties, desired mixing outcomes, and efficiency.

Here are some key aspects of Mixer cum Mixing Technology:

Mixer Types: There are various types of mixers, such as paddle mixers, ribbon blenders, high-shear mixers, and planetary mixers, each suited to specific applications. The choice of mixer depends on the materials being mixed and the desired results.

Mixing Techniques: Mixing technology includes a range of techniques and strategies to achieve thorough and uniform mixing. These techniques may involve the use of specific mixing profiles, impeller designs, agitation methods, and other parameters.

Material Properties: Understanding the physical and chemical properties of the materials being mixed is crucial. Viscosity, density, particle size, and reactivity are some of the properties that can influence the choice of mixer and mixing technology.

Process Control: Mixing technology often involves the use of process control systems and sensors to monitor and adjust the mixing process in real-time to achieve the desired product quality.

Scale and Capacity: Mixer cum Mixing Technology can be applied on various scales, from laboratory and pilot-scale equipment to large industrial mixers. Scalability and capacity are important considerations.

Energy Efficiency: Efficient mixing technology seeks to minimize energy consumption while achieving the desired level of mixing.

Cleanability and Hygiene: In industries like food and pharmaceuticals, mixing technology must comply with stringent hygiene and cleaning standards to prevent contamination.

Safety: Safety is a key consideration, as the mixing of certain materials can pose hazards. Mixing technology may involve safety features and containment systems.

Quality Control: Mixing technology plays a role in quality control and consistency of products, ensuring that the final product meets the desired specifications.

In summary, “Mixer cum Mixing Technology” refers to the combination of mixing equipment and the knowledge and methods used to achieve effective mixing of materials. It is a broad field with applications in numerous industries where material blending is a critical part of the manufacturing or production process.

The term “Blenders cum Blending Technology” refers to the combination of blending equipment, such as blenders, and the associated technological knowledge and methods used to achieve thorough and effective blending of different materials or substances. This concept encompasses both the physical equipment used for blending and the underlying principles and techniques that are employed to optimize the blending process.

Blenders are mechanical devices or equipment designed to mix and homogenize various materials, including liquids, powders, or solids. Blending technology involves a comprehensive understanding of the principles and strategies used to achieve consistent and uniform mixing of materials, taking into account factors such as material properties, desired blending outcomes, and process efficiency.

Here are some key aspects of Blenders cum Blending Technology:

Blender Types: There are various types of blenders, such as ribbon blenders, paddle blenders, high-shear blenders, and fluidized bed blenders, each designed for specific applications. The choice of blender depends on the materials being blended and the desired results.

Blending Techniques: Blending technology encompasses a range of techniques and strategies to achieve thorough and uniform blending. These techniques may involve the use of specific blending profiles, mixing times, and other parameters.

Material Properties: Understanding the physical and chemical properties of the materials being blended is crucial. Particle size, density, flow characteristics, and other material properties can influence the choice of blender and blending technology.

Process Control: Blending technology often involves the use of process control systems and sensors to monitor and adjust the blending process in real-time to achieve the desired blend quality.

Scale and Capacity: Blenders cum Blending Technology can be applied at various scales, from laboratory and pilot-scale equipment to large industrial blenders. Scalability and capacity considerations are important.

Energy Efficiency: Efficient blending technology aims to minimize energy consumption while achieving the desired level of blending.

Cleanability and Hygiene: In industries such as food and pharmaceuticals, blending technology must comply with stringent cleanliness and hygiene standards to prevent contamination.

Safety: Safety is a key consideration, as the blending of certain materials can pose hazards. Blending technology may involve safety features and containment systems.

Quality Control: Blending technology plays a role in quality control and ensuring that the final product meets the desired specifications.

In summary, “Blenders cum Blending Technology” refers to the combination of blending equipment and the knowledge and methods used to achieve effective blending of materials. It is a broad field with applications in numerous industries where material blending is a critical part of the manufacturing or production process.

Mixers and blenders come in various types and designs, each suited to specific applications and materials. Here’s a list of some common types of mixers and blenders:

Ribbon Blenders: Ribbon blenders have a ribbon-like agitator that moves materials in a counter-flow pattern. They are suitable for dry and powdery materials, such as spices, chemicals, and food ingredients.

Paddle Mixers: Paddle mixers use paddles or blades to mix materials. They are often used for mixing wet and heavy materials, like dough, ceramics, and plastics.

High-Shear Mixers: High-shear mixers use high-speed rotating blades or impellers to disperse, emulsify, or homogenize materials. They are used in the pharmaceutical, cosmetic, and food industries.

Planetary Mixers: Planetary mixers have a rotating, planetary motion that ensures thorough mixing. They are commonly used in baking for dough and in laboratories for various applications.

Fluidized Bed Mixers: These mixers suspend and fluidize particles in an air or gas stream. They are used for coating, granulating, and mixing applications in the pharmaceutical and food industries.

Tumbling Mixers: Tumbling mixers consist of a drum that rotates, causing materials inside to tumble and mix. They are used for gentle mixing of fragile materials and for coating applications.

Static Mixers: Static mixers don’t have moving parts; instead, they rely on the design of internal baffles to mix materials as they flow through the mixer. They are used for continuous blending of liquids and gases.

Banbury Mixers: Banbury mixers are intensive internal mixers designed for rubber and plastics processing. They have a tangential counter-rotating action.

Continuous Mixers: Continuous mixers blend materials continuously and are used in applications like food processing and chemical manufacturing.

Cone Blenders: Cone blenders have a conical shape and are used for dry powder blending, ensuring a uniform mix.

Sigma Blade Mixers: Sigma blade mixers have blades shaped like the Greek letter sigma. They are used for kneading, mixing, and blending high-viscosity materials, such as rubber and dough.

Double-Cone Blenders: Double-cone blenders consist of two conical sections joined at the apex. They are used for gentle blending of dry materials.

V-Blenders: V-blenders have a V-shaped chamber with an agitator. They are commonly used for blending powders and granules.

Emulsifying Mixers: Emulsifying mixers are designed for creating emulsions and dispersions, particularly in the cosmetic and pharmaceutical industries.

High-Speed Dispersion Mixers: These mixers are equipped with high-speed agitators for rapid dispersion and mixing of materials.

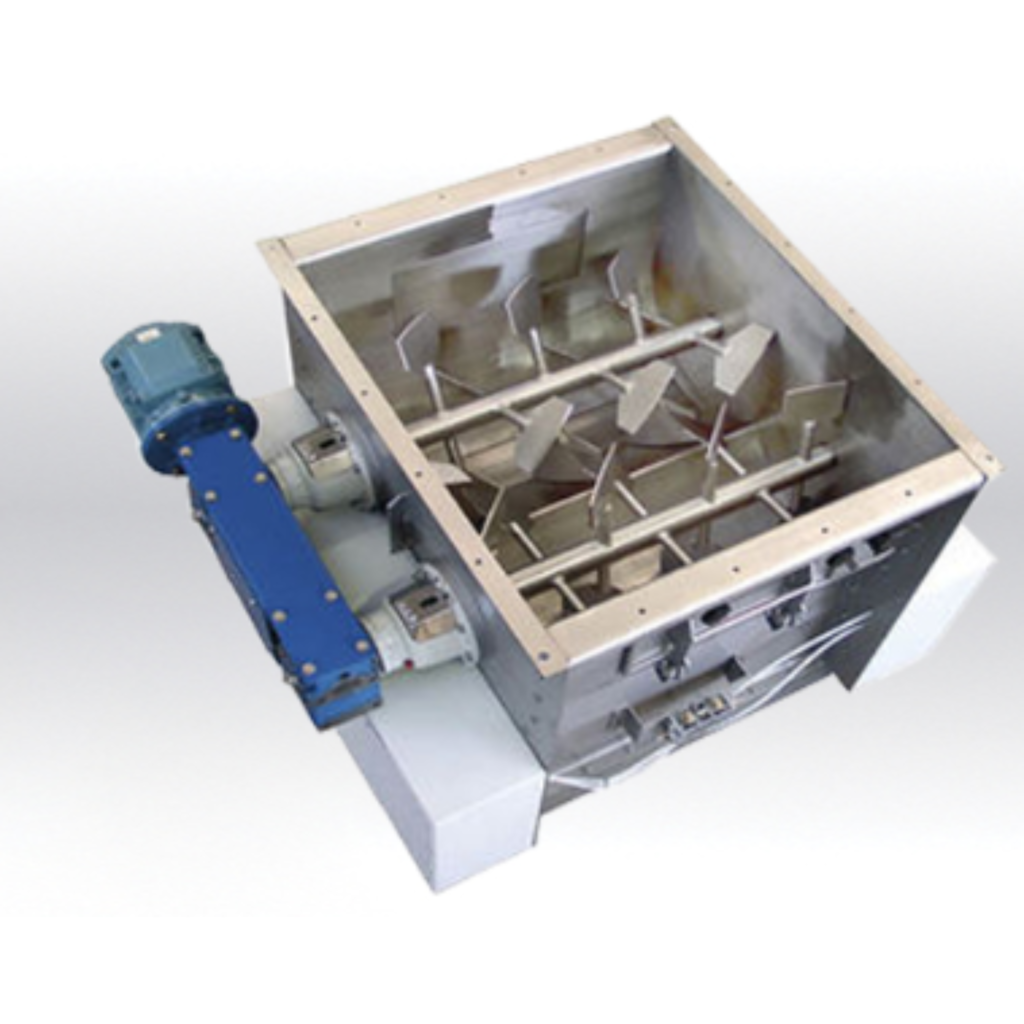

Twin-Shaft Mixers: Twin-shaft mixers have two parallel shafts with paddles or blades. They are used for mixing concrete, mortar, and other building materials.

Pneumatic Conveying Mixers: These mixers use pneumatic systems to transport and mix materials in a continuous flow.

Multi-Shaft Mixers: Multi-shaft mixers have multiple shafts and agitators, allowing for complex and thorough mixing.

The choice of mixer or blender depends on the specific application, materials to be mixed, the desired result, and various operational factors. Different industries and processes require different types of mixers and blenders to meet their unique mixing needs.

Mixers and blenders are versatile equipment used in a wide range of industries and applications to achieve the homogenous mixing of different materials. Their primary purpose is to blend, combine, or agitate substances to create a uniform mixture or product. Here are some common applications of mixers and blenders:

Food and Beverage Industry:

- Mixing ingredients for bakery products, such as dough and batter.

- Homogenizing milk and dairy products.

- Blending powders for beverage production, like instant coffee or powdered drink mixes.

- Preparing sauces, dressings, and condiments.

- Mixing ingredients for processed foods.

Pharmaceutical Industry:

- Blending active pharmaceutical ingredients (APIs) with excipients to create drug formulations.

- Mixing powders for tablet and capsule production.

- Homogenizing liquid medications.

- Preparing creams, ointments, and topical formulations.

Chemical Industry:

- Mixing and blending raw materials for chemical reactions.

- Creating emulsions or suspensions.

- Preparing paints, coatings, and adhesives.

- Formulating fertilizers and pesticides.

Cosmetics and Personal Care:

- Mixing ingredients for skincare products like lotions and creams.

- Preparing shampoos, conditioners, and hair products.

- Formulating perfumes and fragrances.

Plastics and Rubber Industry:

- Blending and compounding polymers and additives.

- Preparing plastic resins for injection molding.

- Mixing rubber compounds for tire production.

Environmental and Wastewater Treatment:

- Mixing chemicals for water treatment, such as coagulation and flocculation.

- Preparing slurry for sewage treatment.

Mining and Minerals:

- Mixing and blending ores and minerals.

- Preparing slurries for mineral processing.

Construction and Building Materials:

- Mixing cement, concrete, and mortar.

- Preparing additives and coatings for construction materials.

Biotechnology and Pharmaceuticals:

- Mixing cell cultures and bioprocess materials.

- Preparing biopharmaceutical products.

Laboratory and Research:

- Laboratory-scale mixers and blenders are used for research and development in various fields, including chemistry, biology, and material science.

Agriculture:

- Mixing fertilizers and agricultural chemicals.

- Preparing animal feeds.

Adhesives and Sealants:

- Mixing and blending adhesive compounds.

- Preparing sealants and caulk.

Waste Management:

- Mixing and treating waste materials and sludges.

Paint and Coatings Industry:

- Mixing paint formulations for residential, commercial, and industrial applications.

Energy Production:

- Preparing and mixing fuels, such as biomass pellets.

Automotive and Aerospace:

- Mixing lubricants, coolants, and other automotive fluids.

Metalworking and Foundries:

- Blending metal powders and compounds.

These are just a few examples of the many applications of mixers and blenders across various industries. The specific type of mixer or blender used can vary depending on the materials being processed and the desired results. The versatility of these machines makes them essential tools in manufacturing and production processes.

The design calculations for mixers and blenders can vary significantly based on the specific type of mixer, the materials being mixed, and the desired results. However, there are some common design considerations and calculations that are typically applied during the design process. Here are key aspects to consider:

Material Properties:

- Density (ρ): The mass per unit volume of the material.

- Viscosity (μ): The resistance to flow.

- Particle Size and Distribution: Information about the size and distribution of particles in the mix.

- Cohesion: A measure of the material’s stickiness.

- Flow Characteristics: Information about the material’s flow behavior.

Mixing Time: Determining the time required for achieving the desired level of homogeneity. This may involve empirical testing and trials.

Blending Speed: Calculating the required rotational or linear speed of the mixer’s agitator or blades to achieve adequate mixing based on material properties.

Mixing Power: Estimating the power consumption of the mixer based on the mixing speed and material properties. This is often calculated using empirical equations.

Vessel Geometry: Selecting the appropriate vessel geometry (e.g., cylindrical, conical) to facilitate efficient mixing and avoid dead zones.

Vessel Size: Determining the volume or capacity of the vessel based on the batch size or continuous processing requirements.

Agitator Design:

- Blade or paddle design: Calculating the dimensions and geometry of agitator blades.

- Shaft design: Sizing the shaft for adequate strength.

- Agitator speed: Selecting the appropriate rotational speed for the agitator.

- Agitator power: Calculating the power required to rotate the agitator.

Mixing Profile:

- Designing a mixing profile, including the direction and rate of agitation, to ensure uniform blending.

- Consideration of factors like shear rate, shear stress, and residence time.

Heat Transfer Considerations:

- In some cases, mixers may need to control or enhance heat transfer. In these instances, heat transfer calculations should be incorporated into the design.

Hygiene and Cleanability:

- For industries like food, pharmaceuticals, and cosmetics, design calculations should ensure that mixers can be easily cleaned to prevent cross-contamination.

Safety Considerations:

- Designing safety features such as emergency stops, protective guards, and containment systems to prevent accidents and protect personnel.

Scale-Up Considerations:

- If the mixer design is for laboratory or pilot-scale use, considerations for scaling up to larger production-scale mixers may be necessary.

Quality Control:

- Developing strategies for monitoring and controlling the quality of the final product during the mixing process.

Regulatory Compliance:

- Ensuring that the mixer design complies with relevant industry standards and regulations.

Design calculations for mixers and blenders are often complex and require a deep understanding of material behavior, fluid dynamics, and equipment design principles. Additionally, pilot testing or empirical experimentation is often necessary to validate the design and optimize the mixing process. Collaboration with engineers and experts in the field is essential to ensure a successful mixer or blender design.

Blenders and mixers are essential equipment used in various industries to achieve the uniform blending and mixing of different materials. They come in a variety of types and designs, each tailored to specific applications and materials. Here’s a summary of blenders and mixers:

Blenders:

-

Ribbon Blenders: Use a ribbon-like agitator for blending dry powders and materials.

-

Paddle Mixers: Utilize paddles or blades to mix heavy, wet materials, such as dough or plastics.

-

High-Shear Mixers: Employ high-speed blades or impellers to emulsify and homogenize materials, often used in the pharmaceutical and food industries.

-

Planetary Mixers: Feature a rotating, planetary motion for thorough blending, commonly used in baking and laboratories.

-

Fluidized Bed Mixers: Suspend and fluidize particles for coating and granulation in the pharmaceutical and food industries.

-

Tumbling Mixers: Use a rotating drum for gentle blending, ideal for fragile materials and coating applications.

Mixers:

-

Static Mixers: Mix materials without moving parts, suitable for continuous blending of liquids and gases.

-

Banbury Mixers: Internal mixers designed for rubber and plastics processing.

-

Continuous Mixers: Blend materials continuously, common in the food and chemical industries.

-

Sigma Blade Mixers: Feature blades shaped like the Greek letter sigma and are used for high-viscosity materials like rubber and dough.

-

Double-Cone Blenders: Blend dry materials gently in a conical chamber.

-

V-Blenders: Use a V-shaped chamber with an agitator for mixing powders and granules.

-

Emulsifying Mixers: Create emulsions and dispersions, often in the cosmetic and pharmaceutical industries.

-

High-Speed Dispersion Mixers: Employ high-speed agitators for rapid dispersion and mixing.

-

Twin-Shaft Mixers: Use two parallel shafts with paddles or blades for mixing concrete, mortar, and building materials.

-

Pneumatic Conveying Mixers: Utilize pneumatic systems for transporting and mixing materials.

-

Multi-Shaft Mixers: Incorporate multiple shafts and agitators for complex and thorough mixing.

Blenders and mixers play critical roles in manufacturing, production, research, and development across a wide range of industries, including food and beverage, pharmaceuticals, chemicals, cosmetics, and more.

The choice of the right type of blender or mixer depends on the materials being processed and the desired blending or mixing outcomes.

Their design and operation are based on factors such as material properties, mixing time, agitator design, safety, and regulatory compliance. Successful blending and mixing processes are essential for ensuring product quality and consistency.

If you have specific inquiries about Mixers and blenders or require design services, please contact our Sales Team @ T.E.A.M. Engineer’s Multi-Equipment & Multi-Services Pvt. Ltd. as soon as possible.

Sales & Marketing:

Sales & Marketing:  Service Supports:

Service Supports:  Website:

Website: