Heat Exchangers

Coolers

Coolers are heat exchangers designed to remove heat from a fluid (liquid or gas) and lower its temperature.

They are commonly used in various applications, including refrigeration, air conditioning, and industrial processes.

The working principles of coolers involve the following key aspects:

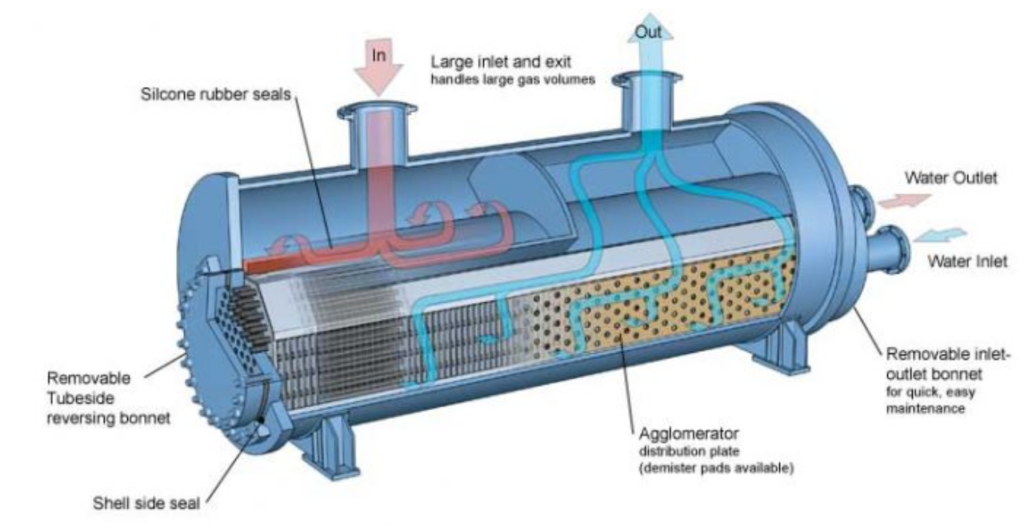

Design: Coolers come in various designs, including shell and tube coolers, plate coolers, and air-cooled coolers, depending on the specific application. They consist of tubes, plates, or surfaces where heat exchange occurs.

Heat Removal: The hot or warm fluid enters the cooler and comes into contact with a cooling medium, typically air or water. Heat is transferred from the fluid to the cooling medium, causing the fluid’s temperature to decrease.

Cooling Medium: The cooling medium absorbs the heat from the fluid, and its temperature may increase as a result. The cooling medium can be circulated through the cooler to maintain efficient heat transfer.

Temperature Reduction: As heat is removed, the fluid’s temperature decreases, resulting in a cooled or chilled fluid. The cooled fluid can then be used in various processes or applications.

Advantages:

Temperature Control: Coolers are essential for maintaining temperature control in various processes, including refrigeration and air conditioning.

Energy Efficiency: They help in reducing energy consumption by cooling fluids and preventing overheating.

Process Optimization: Cooling fluids can improve the efficiency and performance of industrial processes.

Disadvantages:

Space and Cost: Some coolers can be large and costly to install and maintain, which may be a drawback in some applications.

Maintenance: Regular maintenance is required to ensure efficient heat transfer and prevent fouling or corrosion in the cooler tubes or surfaces.

Applications: Coolers are used in a wide range of applications, including:

Refrigeration and air conditioning: Cooling and maintaining low temperatures in residential, commercial, and industrial systems.

Industrial processes: Cooling hot process fluids, such as chemicals or materials, in manufacturing processes.

Power generation: Cooling steam or other fluids in power plants to improve efficiency.

Oil and gas industry: Cooling and condensing gases and fluids in various production and refining processes.

Summary:

Coolers are essential heat exchangers designed to lower the temperature of fluids by removing heat.

They play a critical role in various industries, including refrigeration, air conditioning, and industrial processes, where temperature control and heat removal are necessary.

Coolers offer advantages such as temperature control and energy efficiency but may require space, maintenance, and cost considerations, depending on their size and application.

Sales & Marketing:

Sales & Marketing:  Service Supports:

Service Supports:  Website:

Website: