from: RAW MATERIALS HANDLING SYSTEMS & CONVEYING TECHNOLOGY & PRODUCTS

Air pollution control systems, often referred to as air pollution control equipment or APC systems, are vital components in process industries that aim to mitigate the release of harmful pollutants and contaminants into the atmosphere.

These systems are essential for minimizing the environmental impact of industrial operations, ensuring compliance with air quality regulations, and safeguarding the health and well-being of both workers and nearby communities.

Definition: Air pollution control systems are a set of engineering technologies and equipment designed to capture, remove, or neutralize harmful pollutants and contaminants from industrial processes and emissions before they are released into the atmosphere.

Key Components and Technologies:

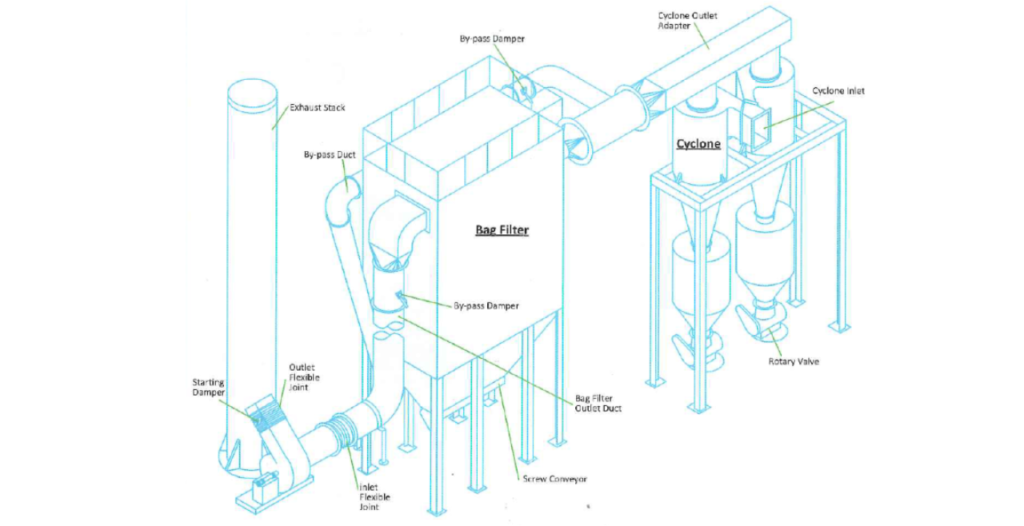

- Particulate Matter (PM) Control: This involves the removal of solid or liquid particles from exhaust gases. Technologies include:

- Electrostatic precipitators (ESPs)

- Baghouses or fabric filters

- Cyclone separators

- Gaseous Emission Control: This addresses the removal of gaseous pollutants like sulfur dioxide (SO2), nitrogen oxides (NOx), and volatile organic compounds (VOCs). Technologies include:

- Scrubbers (wet and dry)

- Selective catalytic reduction (SCR) and selective non-catalytic reduction (SNCR) for NOx control

- Adsorption systems (activated carbon beds) for VOC control

- Industrial Ventilation: Proper ventilation and capture systems ensure that pollutants are contained at the source.

- Thermal Oxidizers: Used to combust VOCs and other hazardous air pollutants.

- Continuous Emission Monitoring Systems (CEMS): These systems measure emissions and provide data for compliance and monitoring.

- Noise Control: In some cases, noise pollution control measures are also considered, which may involve barriers and acoustic treatments.

- Odor Control: In processes where odor emissions are a concern, air pollution control systems may incorporate odor control techniques, such as chemical scrubbers or biofilters.

- Particulate Matter (PM) Control: This involves the removal of solid or liquid particles from exhaust gases. Technologies include:

Importance:

- Environmental Compliance: Air pollution control systems are essential for ensuring that industrial operations comply with local, national, and international environmental regulations and emissions standards.

- Health and Safety: By reducing the release of harmful pollutants, these systems protect the health and safety of workers and nearby residents.

- Environmental Conservation: They help reduce the environmental impact of industrial activities, minimizing the damage to ecosystems and air quality.

Applications:

- Air pollution control systems are utilized in a wide range of process industries, including manufacturing, chemical production, power generation, metal processing, petrochemicals, and waste incineration, among others.

- These systems are particularly critical in industries where the release of hazardous air pollutants, greenhouse gases, and particulate matter can have severe consequences.

Challenges and Maintenance:

- Regular maintenance and monitoring of air pollution control systems are essential to ensure their effectiveness and efficiency.

- Challenges may include addressing changing emission profiles, optimizing energy consumption, and addressing potential equipment wear and tear.

In summary, Air Pollution Control Systems in process industries are essential for managing and reducing the emission of harmful pollutants, protecting the environment, ensuring regulatory compliance, and safeguarding human health and safety. These systems incorporate a variety of technologies and components tailored to the specific pollutants and challenges associated with each industrial process.

If You Have Specific Inquiries for the same Or Require Design Services, Please Contact Our Sales Team @ T.E.A.M. Engineer’s Multi-Equipment & Multi-Services Pvt. Ltd. As Soon As Possible.

Sales & Marketing:

Sales & Marketing:  Service Supports:

Service Supports:  Website:

Website: