Mixers/Blenders Technology/Products

Pneumatic Blenders

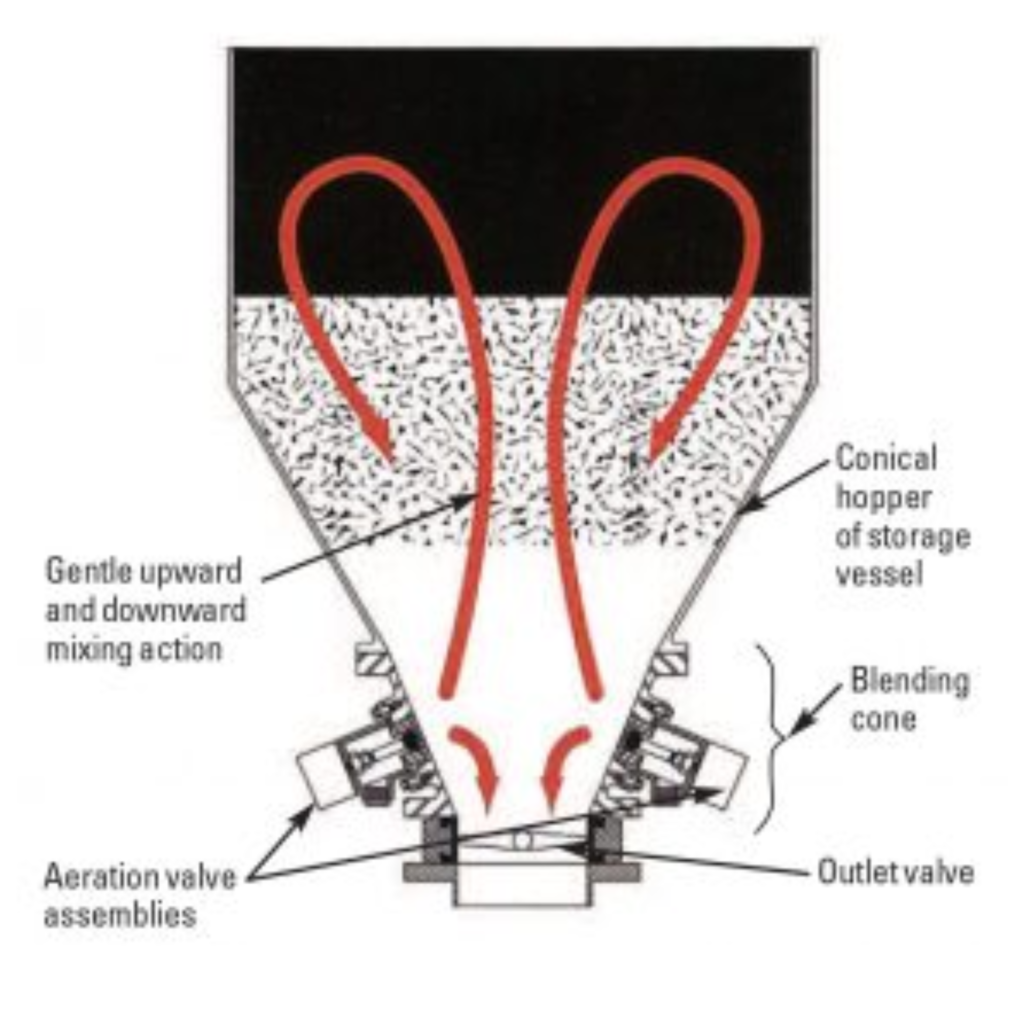

Pneumatic blenders are also known as air blenders or air-driven blenders, are the best-specialized blending devices used in blending technology to combine dry powders, granules, and other solid materials. They use compressed air to create a fluidized bed of material, promoting mixing and blending. Here’s an overview of their working principle, advantages, and disadvantages.

| Best Working Principle: The working principle of pneumatic blenders relies on fluidization, which involves suspending solid particles in a stream of compressed air. The key working principles include: |

| Loading: The dry materials to be blended are loaded into a mixing chamber or vessel, often referred to as a fluidized bed chamber. |

| Fluidization: Compressed air is introduced into the bottom of the mixing chamber through a distributor plate or diffuser. The high-velocity air flow creates an upward force, suspending and fluidizing the solid particles within the chamber. |

| Mixing: As the particles become fluidized, they behave like a dense, swirling fluid. This fluidized state allows for efficient mixing and blending as the particles collide and intermingle. |

| Discharging: Once the blending process is complete, the blended mixture can be discharged from the chamber. |

| Best Advantages of Pneumatic Blenders: |

| Uniform Mixing: Pneumatic blenders offer excellent mixing uniformity, ensuring that all components are evenly distributed throughout the mixture. |

| Gentle Mixing: The mixing action is gentle on sensitive or fragile materials, reducing the risk of product degradation. |

| Versatility: They can handle a wide range of materials, including powders, granules, and materials with varying particle sizes. |

| Customization: The mixing intensity can be adjusted by varying the air velocity, allowing for customization to meet specific blending requirements. |

| Ease of Cleaning: Many pneumatic blenders are designed for easy cleaning and sanitation, making them suitable for industries with strict hygiene requirements. |

| Disadvantages of Pneumatic Blenders: |

| Batch Process: Pneumatic blenders are typically used for batch processing, which may not be ideal for continuous production lines. |

| Complex Design: The presence of the fluidization chamber, distributor plate, and compressed air system adds complexity to the blender’s design, which may require more maintenance over time. |

| Limited for High-Shear Mixing: They may not be suitable for applications that require high-shear mixing or intense agitation. |

| Energy Consumption: Running the compressor for compressed air can consume significant energy. |

| Material Flow Issues: Some materials may not fluidize well or may require special handling within pneumatic blenders, potentially leading to uneven mixing or material buildup. |

In summary, pneumatic blenders are efficient and versatile mixing devices known for their excellent mixing uniformity and gentle blending action. They are particularly suitable for applications requiring minimal product degradation and high mixing uniformity. However, their batch processing nature and reliance on compressed air may limit their use in certain production scenarios. The choice of blender type should be based on the specific characteristics of the materials and the blending requirements of the process.

Sales & Marketing:

Sales & Marketing:  Service Supports:

Service Supports:  Website:

Website: