Mixers/Blenders Technology/Products

Planetary Mixers:

Planetary mixers are versatile blending and mixing devices commonly used in various industries, including food processing, pharmaceuticals, cosmetics, and chemicals.

They are known for their distinctive planetary motion, which involves the simultaneous rotation of the mixing bowl and a central agitator or mixing tool. Here’s an overview of their working principle, advantages, and disadvantages.

| Working Principle: The working principle of planetary mixers involves a combination of two types of motion: |

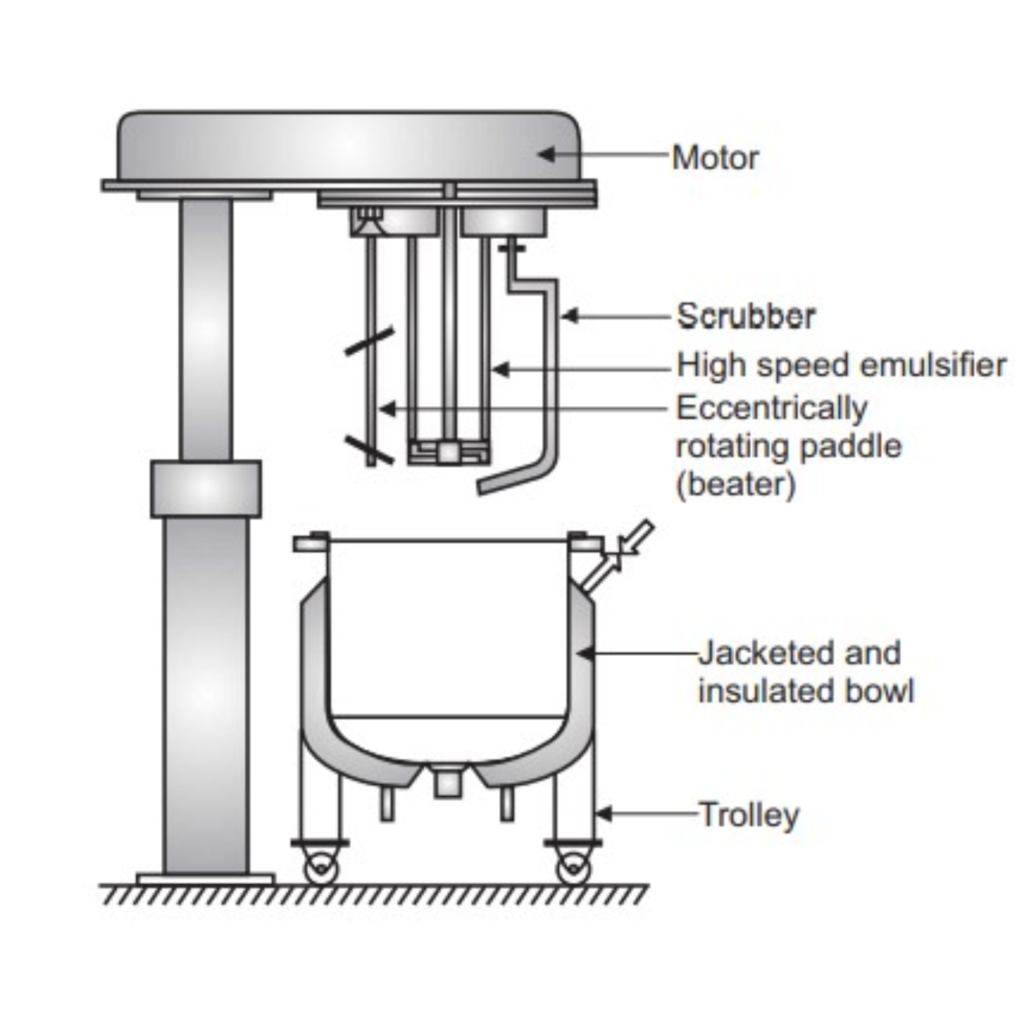

| Planetary Motion: The mixing bowl is typically mounted on a turntable or orbiting platform. This platform rotates around the central axis of the mixer while simultaneously rotating on its own axis. This dual rotation creates a planetary motion, where the agitator moves along a circular path within the mixing bowl. |

| Agitator Rotation: Inside the mixing bowl, there is a central agitator, which can have various designs such as a paddle, blade, or dough hook. This agitator rotates on its own axis while following the circular path defined by the planetary motion. |

| Advantages of Planetary Mixers: |

| Uniform Mixing: Planetary mixers provide excellent mixing uniformity, ensuring that all components are evenly distributed throughout the mixture. |

| Versatility: They can handle a wide range of materials, including liquids, dough, powders, and semi-solid substances. |

| Customization: Various mixing tools can be used with planetary mixers, allowing for customization to meet specific blending requirements, such as dough kneading, beating, whipping, or stirring. |

| High Shear Capability: Some planetary mixers are designed to provide high shear mixing, making them suitable for applications requiring particle size reduction or emulsification. |

| Ease of Operation: They are relatively easy to operate, and many models offer variable speed and mixing time controls for precise blending. |

| Compact Design: Planetary mixers are often compact and suitable for both laboratory and small- to medium-scale production settings. |

| Disadvantages of Planetary Mixers: |

| Batch Process: They are typically used for batch processing, which may not be ideal for continuous production lines. |

| Size Limitations: While compact models are suitable for small to medium-sized batches, they may not be practical for large-scale production. |

| Complex Design: The presence of multiple moving parts, including the turntable and agitator, can make maintenance and cleaning more complex compared to simpler mixers. |

| Limited for High-Volume Production: Planetary mixers may not be cost-effective for high-volume production due to their batch processing nature. |

| Heat Generation: The mixing action can generate heat, which may be undesirable for temperature-sensitive materials. |

| Summary: Planetary mixers are valuable mixing devices known for their excellent mixing uniformity and versatility. They are suitable for a wide range of applications, from baking and food processing to pharmaceuticals and cosmetics. While they are effective for small to medium-sized batches, they may not be the most efficient choice for large-scale, continuous production processes. The choice of mixer type should be based on the specific characteristics of the materials and the blending requirements of the process. |

Sales & Marketing:

Sales & Marketing:  Service Supports:

Service Supports:  Website:

Website: