Rotary Air Valve (RAL)

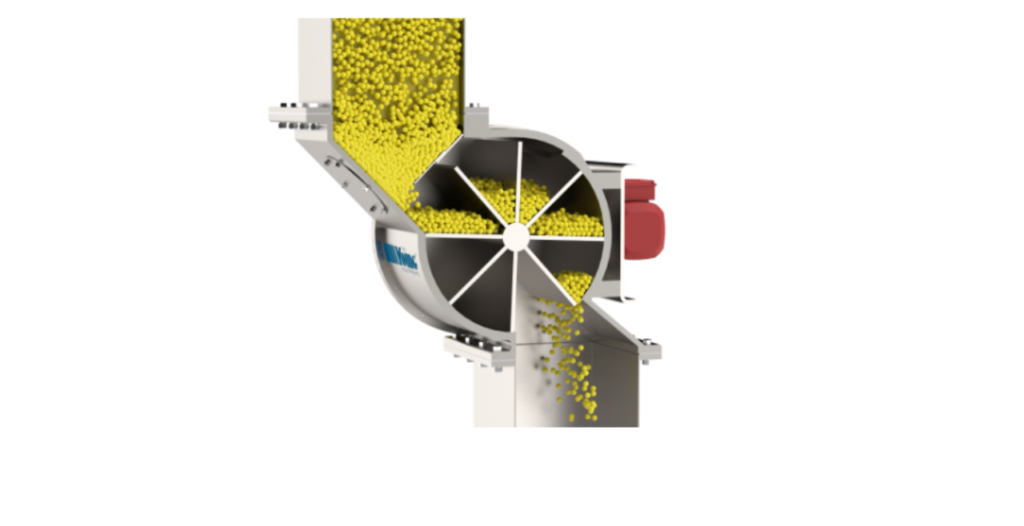

Offset or Side Entry Type RAL

Working Principles: An Offset or Side Entry Rotary Airlock Valve is a type of rotary valve used in material handling and pneumatic conveying systems. Unlike the traditional Drop-Thru Rotary Valve, the Offset RAL is designed with its inlet and outlet ports located on the side of the valve housing, allowing for material entry and exit from the side. Here’s how it works: |

| Inlet and Outlet Ports: In an Offset RAL, the inlet and outlet ports are situated on the side of the valve housing. |

| Rotor with Pockets: Inside the valve, there is a rotating rotor with pockets or chambers. The rotor continuously rotates, trapping and carrying bulk material from the side inlet toward the side outlet. |

| Material Discharge: As each pocket reaches the side outlet, it releases the material into the downstream equipment or process, which may be positioned horizontally or vertically. |

| Airtight Seal: Similar to other rotary valves, the Offset RAL is designed to maintain an airtight seal between the inlet and outlet. This sealing prevents air leakage, maintains system pressure, and minimizes dust emissions. |

| Advantages: |

| Versatile Orientation: Can be used in both horizontal and vertical material handling systems due to its side-entry design. |

| Airtight Seal: Maintains an airtight seal between the inlet and outlet, preventing air leakage and preserving system efficiency. |

| Material Flow Control: Provides precise control over the flow of bulk materials, allowing for regulated and continuous material transfer. |

| Continuous Operation: Capable of continuous operation, ensuring a steady and controlled material flow. |

| Disadvantages: |

| Maintenance: Requires regular maintenance to ensure proper functioning, including inspection of rotor vanes, seals, and bearings. |

| Material Jamming: As with other rotary valves, certain materials, such as sticky or abrasive substances, may lead to jamming or wear of the valve components. |

| Applications: |

| Offset or Side Entry Rotary Airlock Valves are versatile and find applications in various industries and systems, including: |

| Pneumatic Conveying: Used to control the flow of bulk materials in pneumatic conveying systems, whether in a horizontal or vertical orientation. |

| Food Processing: Employed in food processing and manufacturing for the handling of ingredients, powders, and granules. |

| Pharmaceuticals: Utilized in pharmaceutical manufacturing where precise material transfer is required, often in a vertical orientation. |

| Chemicals: In chemical processing to control the flow of chemicals and powders. |

| Plastics: In plastics processing for conveying plastic pellets and resin in horizontal or vertical systems. |

| Agriculture: Commonly used in grain handling and feed processing. |

| Summary: |

| An Offset or Side Entry Rotary Airlock Valve is a versatile rotary valve designed for material handling and pneumatic conveying systems. Its unique side-entry design allows for use in both horizontal and vertical orientations. The valve provides precise material flow control, maintains an airtight seal, and operates continuously. However, like other rotary valves, it requires regular maintenance to ensure reliability and performance in industrial processes. Proper selection and maintenance are crucial for their effectiveness in various applications and system orientations. |

Sales & Marketing:

Sales & Marketing:  Service Supports:

Service Supports:  Website:

Website: