Agitators Technology & Products

Agitators are essential components in various industrial processes that require mixing, blending, or agitation of liquids and/or solids.

The choice of agitator type depends on the specific process requirements and the properties of the materials being mixed.

Here are some common types of agitators and an overview of how to design them:

Types of Agitators: (See the link please)

Propeller Agitators: These are simple, low-cost agitators with flat, angled blades that rotate to create flow and agitation. They are commonly used for blending and low-viscosity applications.

Turbine Agitators: Turbine agitators have multiple curved blades and are used for high-viscosity fluids and in applications that require strong vertical flow.

Paddle Agitators: Paddle agitators have flat blades and are suitable for mixing viscous materials. They are often used in the food and chemical industries.

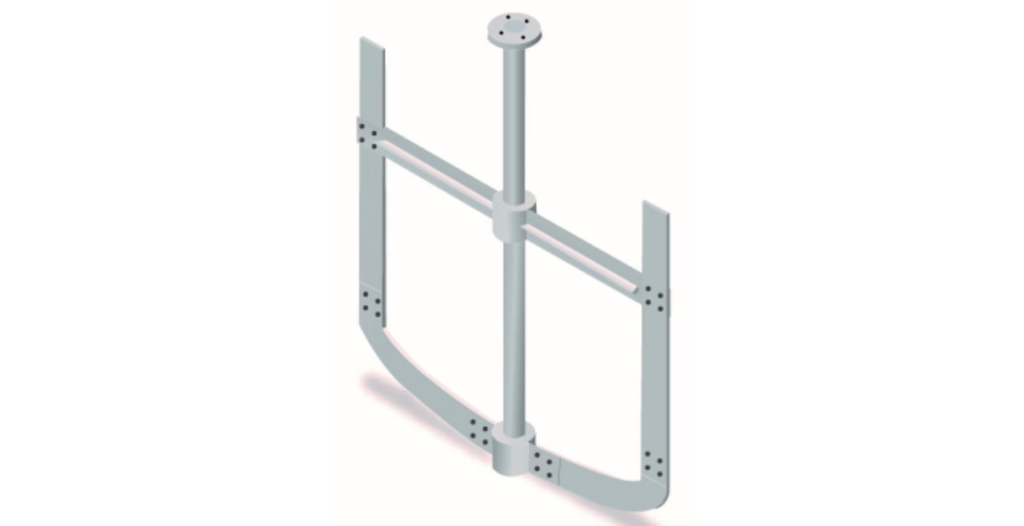

Anchor Agitators: Anchor agitators have a single or multiple arms with curved or helical blades. They are effective in mixing viscous materials and preventing material buildup on the vessel walls.

High Shear Mixers: These agitators generate high shear forces and are used for processes like emulsification, homogenization, and dispersion.

Magnetic Agitators: Magnetic agitators use a magnetic field to rotate an impeller inside a sealed vessel, making them suitable for sterile and aseptic processes.

Agitator Bead Mills: These are specialized agitators used in the production of fine particle-size materials, particularly in the pharmaceutical and chemical industries.

Ribbon Blenders: While not traditional agitators, ribbon blenders consist of a horizontal, U-shaped trough with a ribbon-like mixing element that rotates. They are used for gentle mixing and blending of powders and granular materials.

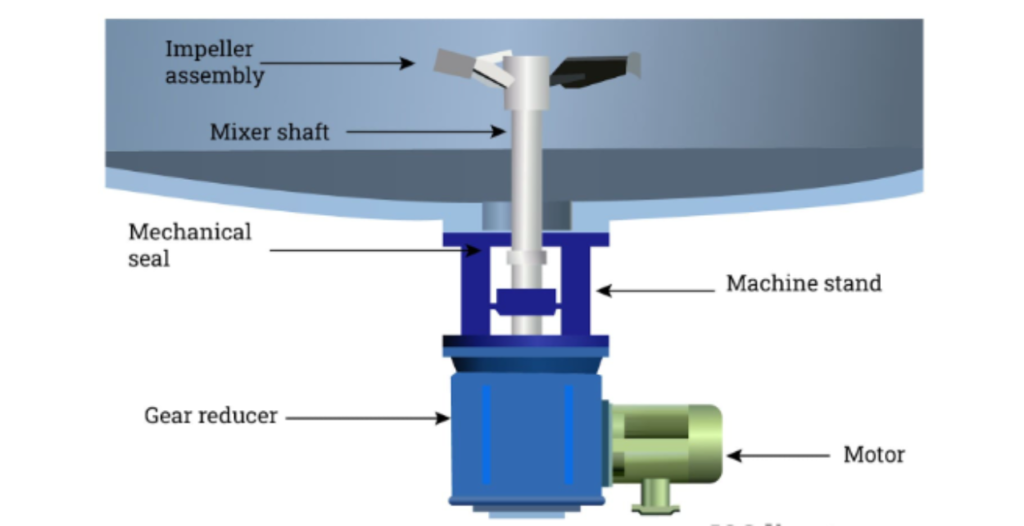

Designing Agitators: Designing agitators involves considering the following factors:

- Process Requirements: Understand the specific mixing requirements, including mixing time, shear rate, and product properties.

- Fluid Properties: Consider the viscosity, density, and rheological properties of the material.

- Vessel Geometry: The size, shape, and dimensions of the vessel impact agitator selection.

- Agitator Speed: Determine the optimal agitator speed for the desired mixing intensity.

- Agitator Material: Select materials that are compatible with the process and resist corrosion or wear.

- Drive System: Choose the appropriate drive system, such as an electric motor or a gearbox.

- Sealing and Lubrication: Ensure the agitator is properly sealed to prevent leakage and adequately lubricated for smooth operation.

Market Demand: (Open The Link Please)

The demand for agitators remains strong in various industries, including chemical processing, pharmaceuticals, food and beverages, wastewater treatment, and more.

Several factors contribute to the demand for agitators in the market:

Process Optimization: Industries continually seek to improve their processes for efficiency and product quality, which often involves better mixing and agitation.

Environmental Regulations: The need for effective wastewater treatment and pollution control drives demand for agitators used in water and wastewater treatment processes.

Pharmaceutical and Biotechnology: The growth of the pharmaceutical and biotechnology sectors, where sterile and precise mixing is crucial, contributes to the demand for specialized agitators.

Food and Beverage: The food and beverage industry requires agitators for mixing ingredients, emulsification, and other processes.

Energy and Petrochemicals: Agitators are vital for the production of fuels, chemicals, and petrochemical products.

R&D and Innovation: Advances in materials, technology, and design continue to drive innovation in the agitator industry.

Overall, the demand for agitators is closely tied to industrial production and innovation, making it a dynamic and growing market, especially as industries continue to seek efficient and sustainable solutions.

If You Have Specific Inquiries for the same Or Require Design Services, Please Contact Our Sales Team @ T.E.A.M. Engineer’s Multi-Equipment & Multi-Services Pvt. Ltd. As Soon As Possible.

Sales & Marketing:

Sales & Marketing:  Service Supports:

Service Supports:  Website:

Website: