CONVEYORS

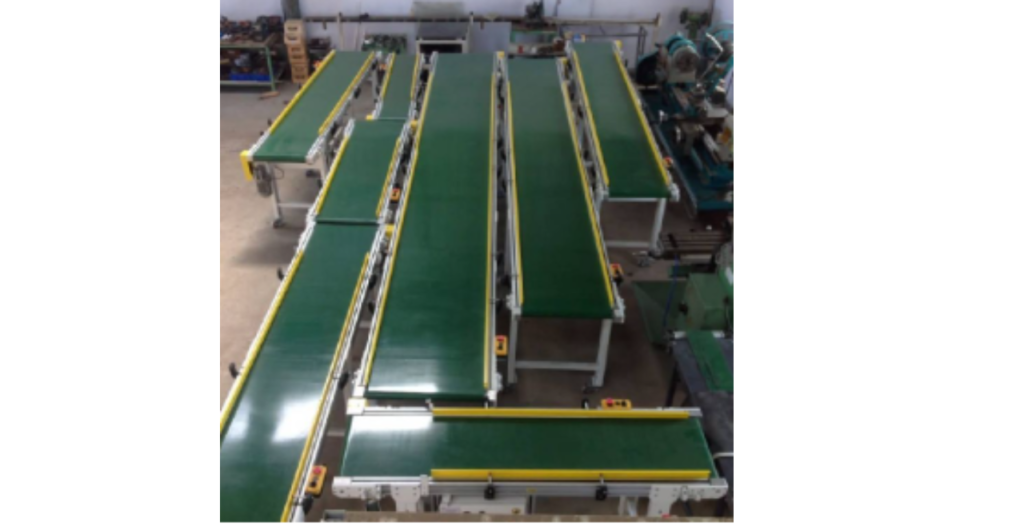

Belt Conveyors

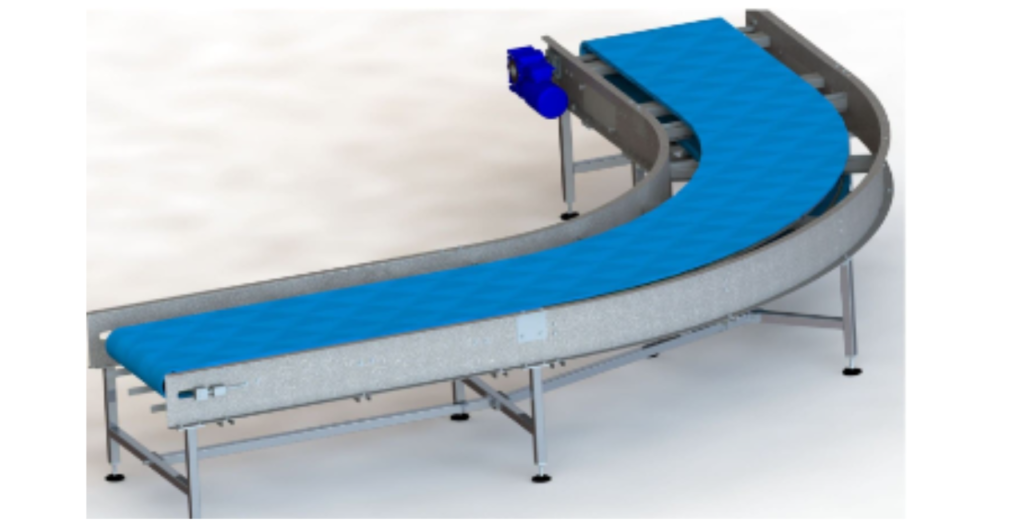

| Belt conveyors are material handling systems that use continuous belts made of various materials (e.g., rubber, PVC, fabric) to transport bulk materials horizontally or at an incline. The working principles of belt conveyors involve the following key aspects: |

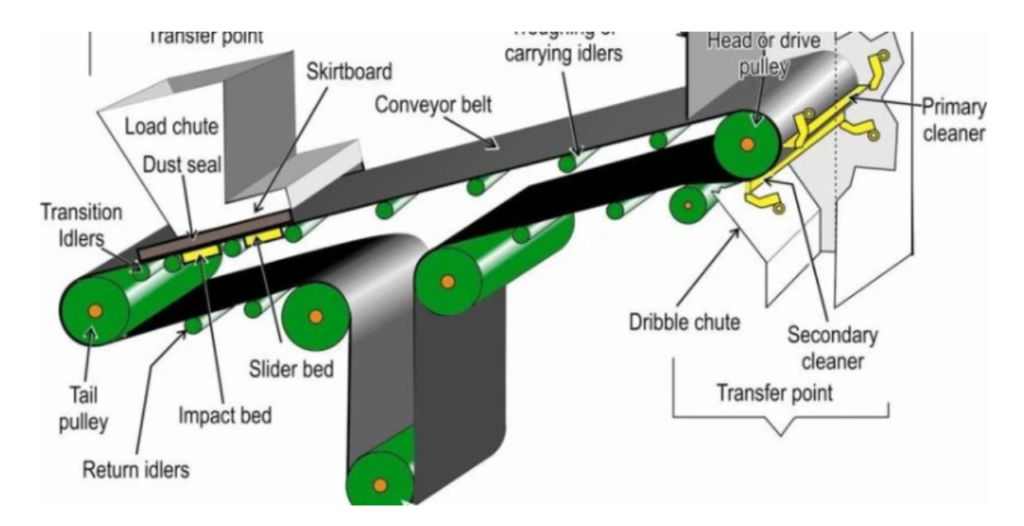

| Belt: A continuous loop of material, the conveyor belt, is supported by rollers or idlers along its path. The belt typically has a flat or troughed shape, depending on the material being transported. |

| Drive Mechanism: A motorized pulley or drive roller is used to move the conveyor belt. The drive mechanism provides the necessary power to propel the belt and transport materials. |

| Load and Unload Points: Material is loaded onto the conveyor at the loading point, and it is unloaded at the discharge point. Load and unload mechanisms, such as chutes or hoppers, are often used to control the material flow. |

| Continuous Operation: Belt conveyors operate continuously, providing a steady and controlled flow of materials. |

| Advantages: |

| Versatility: Belt conveyors are highly versatile and can handle a wide range of materials, from small particles to large bulk items. |

| Efficiency: They offer efficient and continuous material transport, making them suitable for high-capacity operations. |

| Customizability: Belt conveyors can be customized to meet specific application requirements, including belt material, width, length, and speed. |

| Reduced Labor: Automated belt conveyors reduce the need for manual material handling, improving labor efficiency. |

| Minimal Maintenance: When properly maintained, belt conveyors have minimal maintenance requirements, resulting in lower operating costs. |

| Disadvantages: |

| Maintenance: While they require less maintenance compared to some other conveyors, belt conveyors still need periodic cleaning, belt tensioning, and roller/idler maintenance. |

| Space Requirements: Belt conveyors may require a significant amount of floor space, particularly for longer transport distances. |

| Material Spillage: Incline belt conveyors may experience material spillage at higher incline angles, which can lead to cleanup and maintenance challenges. |

| Applications: |

| Belt conveyors are used in a wide range of industries and applications, including: |

| Manufacturing: Moving components and products along assembly lines. |

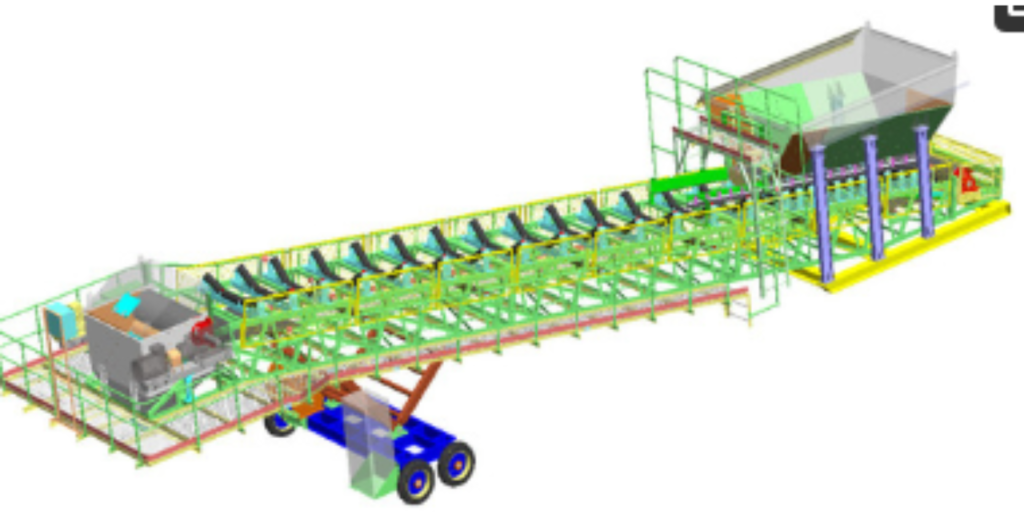

| Mining and Minerals: Transporting ores, aggregates, and bulk materials. |

| Warehousing and Distribution: Sorting and transporting packages and parcels. |

| Agriculture: Handling grains, seeds, and agricultural products. |

| Food and Beverage: Conveying packaged and unpackaged food items. |

| Construction: Transporting construction materials, such as sand, gravel, and concrete. |

| Airports: Handling luggage and cargo at airports. |

| Ports and Shipping: Loading and unloading cargo from ships and trucks. |

| Recycling: Sorting and transporting recyclables in recycling facilities. |

Summary:

Belt conveyors are versatile and efficient material handling systems that use continuous belts to transport bulk materials horizontally or at an incline. They offer advantages such as versatility, efficiency, customizability, and reduced labor requirements. However, they require periodic maintenance, may occupy significant floor space, and may experience material spillage at higher incline angles. Belt conveyors are widely used across various industries for the reliable and continuous transport of a wide range of materials. Proper design, maintenance, and safety measures are essential to ensure their effective and safe operation.

Sales & Marketing:

Sales & Marketing:  Service Supports:

Service Supports:  Website:

Website: