Air Classifier Mill (ACM)

| Air Classifier Mill (ACM) is a specialized type of grinding mill that combines impact grinding with air classification to produce fine powders with a narrow particle size distribution. It’s commonly used in industries requiring precise control over particle size and is often used for materials that are heat-sensitive or need to be processed in a controlled environment. Here’s a detailed overview of Air Classifier Mills, including their working principles, advantages, disadvantages, applications, materials of construction (MOC), and a summary: |

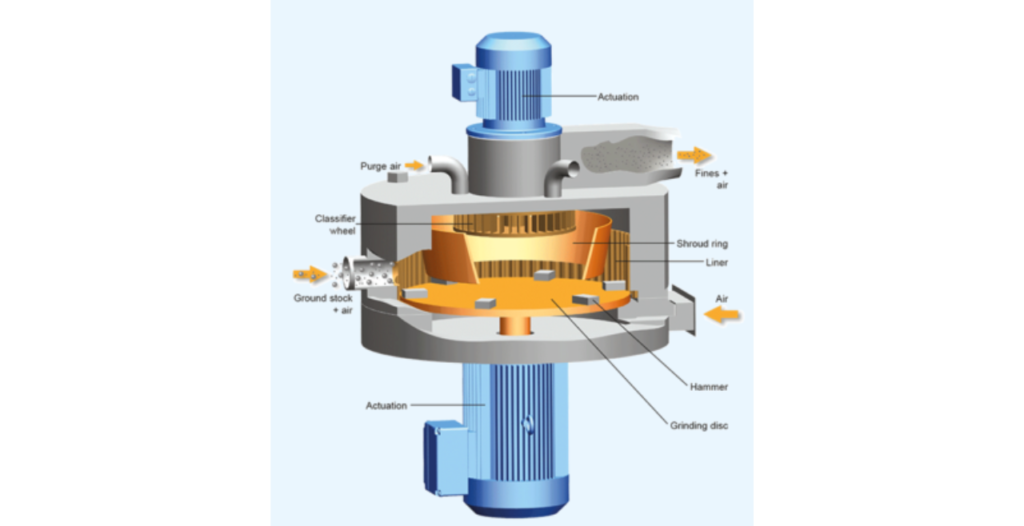

| Working Principles: |

| The working principle of an Air Classifier Mill involves the following steps: |

| Feeding: The material is introduced into the mill through a feed mechanism, typically a screw feeder or a pneumatic conveying system. |

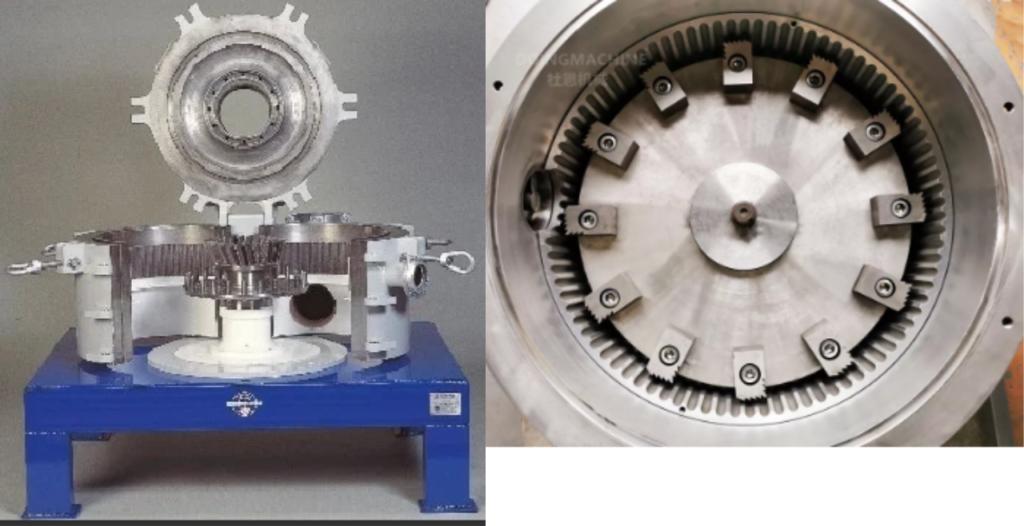

| Grinding: Inside the mill, a high-speed rotor equipped with hammers, pins, or other grinding elements rotates. The material is subjected to impact, compression, and shearing forces as it passes through the grinding zone. This reduces the material to a fine powder. |

| Classification: Simultaneously, air is introduced into the mill, and it carries the ground particles upward into an integrated classifier or separate classifier chamber. The classifier separates the particles based on their size and weight. Fine particles are carried out of the classifier and collected as product, while larger particles are returned to the grinding zone for further size reduction. |

| Discharge: The fine particles are discharged from the mill, often via a pneumatic conveying system, and collected in a separate container. |

| Advantages: |

| Precise Particle Size Control: ACMs offer exceptional control over particle size distribution, making them ideal for applications requiring a narrow particle size range. |

| Uniform Particle Shape: They produce particles with a uniform and well-defined shape, crucial in some industries like pharmaceuticals and cosmetics. |

| High Efficiency: ACMs are highly efficient at reducing the size of materials with minimal heat generation. |

| Low Heat Generation: They generate relatively low heat during operation, making them suitable for preserving heat-sensitive materials. |

| Suitable for Heat-Sensitive Materials: Because of the low heat generation and air classification, ACMs are ideal for processing heat-sensitive materials like some pharmaceuticals. |

| Dust Control: The integrated air classification helps control dust generation during milling. |

| Disadvantages: |

| Complex Design: ACMs can be complex machines to design and operate, particularly for achieving specific particle size distributions. |

| Initial Investment: They can be expensive to purchase and install, especially for specialized or high-capacity models. |

| Maintenance: The high-speed rotation of components can result in wear and tear, necessitating maintenance and replacement. |

| Energy Consumption: ACMs can consume a significant amount of energy, especially when processing tough or hard materials. |

| Applications: |

| Air Classifier Mills find applications in various industries, including: |

| Pharmaceuticals: For milling active pharmaceutical ingredients (APIs) and excipients to fine powders. |

| Cosmetics: In the production of cosmetic powders with precise particle size and shape requirements. |

| Chemical Industry: For reducing the size of chemicals, pigments, and dyes. |

| Food Industry: For grinding spices, herbs, and food additives to fine powders. |

| Minerals and Mining: For reducing the size of minerals and ores. |

| Materials of Construction (MOC): |

| The choice of materials for Air Classifier Mills depends on the specific application and the materials being processed. Common materials of construction include: |

| Stainless Steel: Often used for the main structure and grinding components due to its corrosion resistance and suitability for food and pharmaceutical applications. |

| Hardened Alloys: Used for hammers, pins, or other components that come into direct contact with the material to handle wear and abrasion. |

Summary:

An Air Classifier Mill (ACM) is a specialized size reduction machine used for grinding and classifying materials into fine powders with a narrow particle size

Sales & Marketing:

Sales & Marketing:  Service Supports:

Service Supports:  Website:

Website: