Basket Filter

Basket Filter is a type of filtration device used to remove solid particles from a liquid or gas stream.

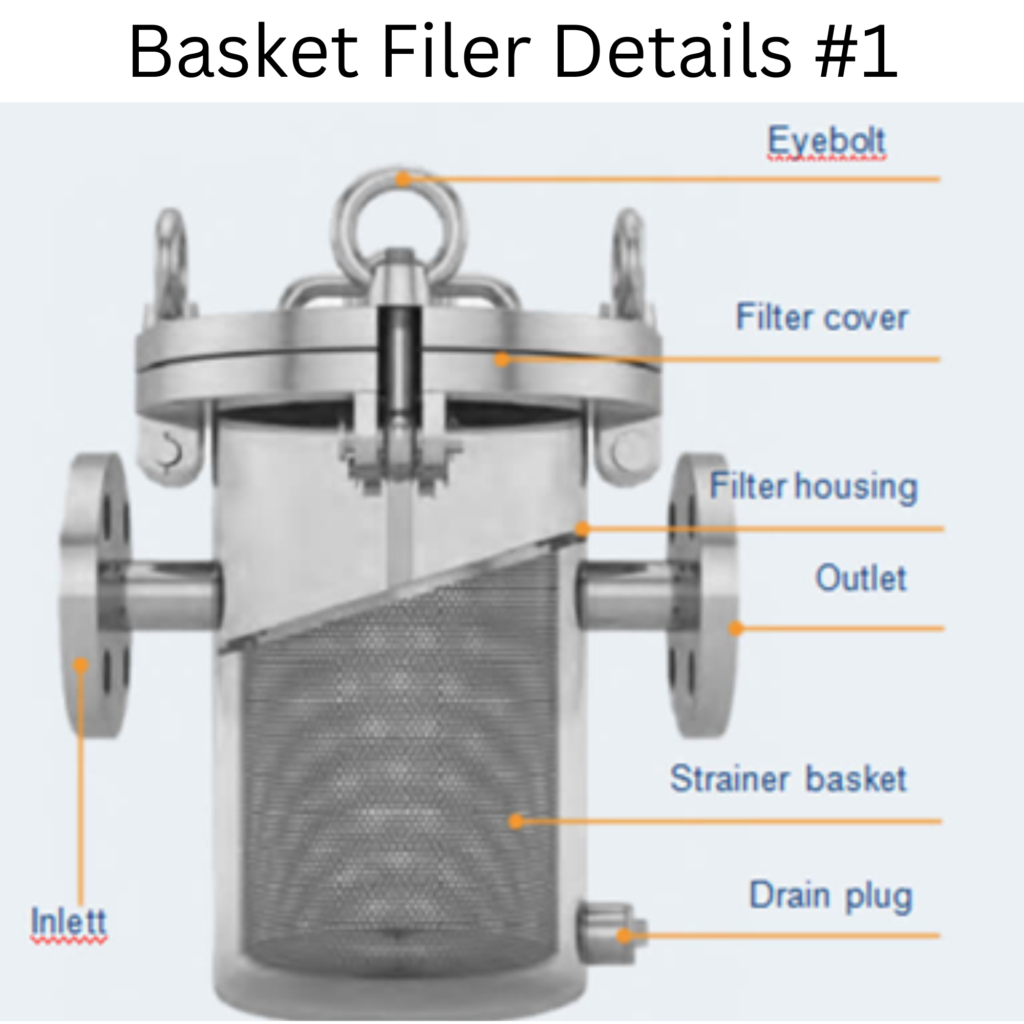

It consists of a cylindrical or basket-shaped housing with a perforated or mesh-lined interior. The basket filter is installed in a pipeline or a vessel, and the fluid to be filtered passes through the filter housing.

The main function of a basket filter is to capture and retain solid contaminants present in the fluid, preventing them from entering downstream equipment or processes.

The solid particles can include debris, dirt, rust, scale, sediments, and other impurities that may be present in the fluid. By removing these particles, the basket filter helps protect sensitive equipment, such as pumps, valves, meters, and heat exchangers, from damage or clogging.

Overall, the Basket Filter plays a vital role in maintaining the quality of fluids and protecting downstream equipment in industries such as oil and gas, chemical processing, pharmaceuticals, food and beverage, water treatment, and many others.

Benefits & Silent Features:

- Efficient Particle Removal: Basket filters effectively remove solid particles, debris, and contaminants from the fluid stream, ensuring the purity and cleanliness of the process fluid. They can capture particles of varying sizes depending on the chosen filtration rating.

- High Contaminant Holding Capacity: The basket-shaped design of these filters allows for a large holding capacity. They can accumulate a significant amount of solid particles before requiring cleaning or replacement, reducing the frequency of maintenance.

- Easy Maintenance and Cleaning: Basket filters are designed for easy maintenance. The filter housing can be opened, and the filter element, typically a basket or cylindrical screen, can be easily accessed and cleaned or replaced. This facilitates quick and convenient maintenance, minimizing downtime.

- Protection for Equipment and Processes: By removing solid particles, basket filters help protect downstream equipment such as pumps, valves, heat exchangers, and instruments from damage and premature wear. They also safeguard sensitive processes and prevent clogging in pipelines and vessels.

- Versatility in Filtration Rating: Basket filters are available in a range of filtration ratings to suit different applications. The mesh or perforated screen lining the filter basket can be selected based on the desired particle size removal, providing flexibility in meeting specific filtration requirements.

- Low-Pressure Drop: Basket filters are designed to minimize pressure drop across the filter element, ensuring efficient flow rates and maintaining system performance. This helps maintain optimal operating conditions and avoids unnecessary energy consumption.

- Compatibility with Various Fluids: Basket filters are compatible with a wide range of fluids, including liquids and gases. They can be constructed using different materials such as stainless steel, carbon steel, or exotic alloys to ensure compatibility with the fluid being filtered and the process environment.

- Robust Construction and Durability: Basket filters are typically constructed using high-quality materials, making them durable and resistant to corrosion, high temperatures, and harsh operating conditions. This ensures their longevity and reliability in demanding industrial environments.

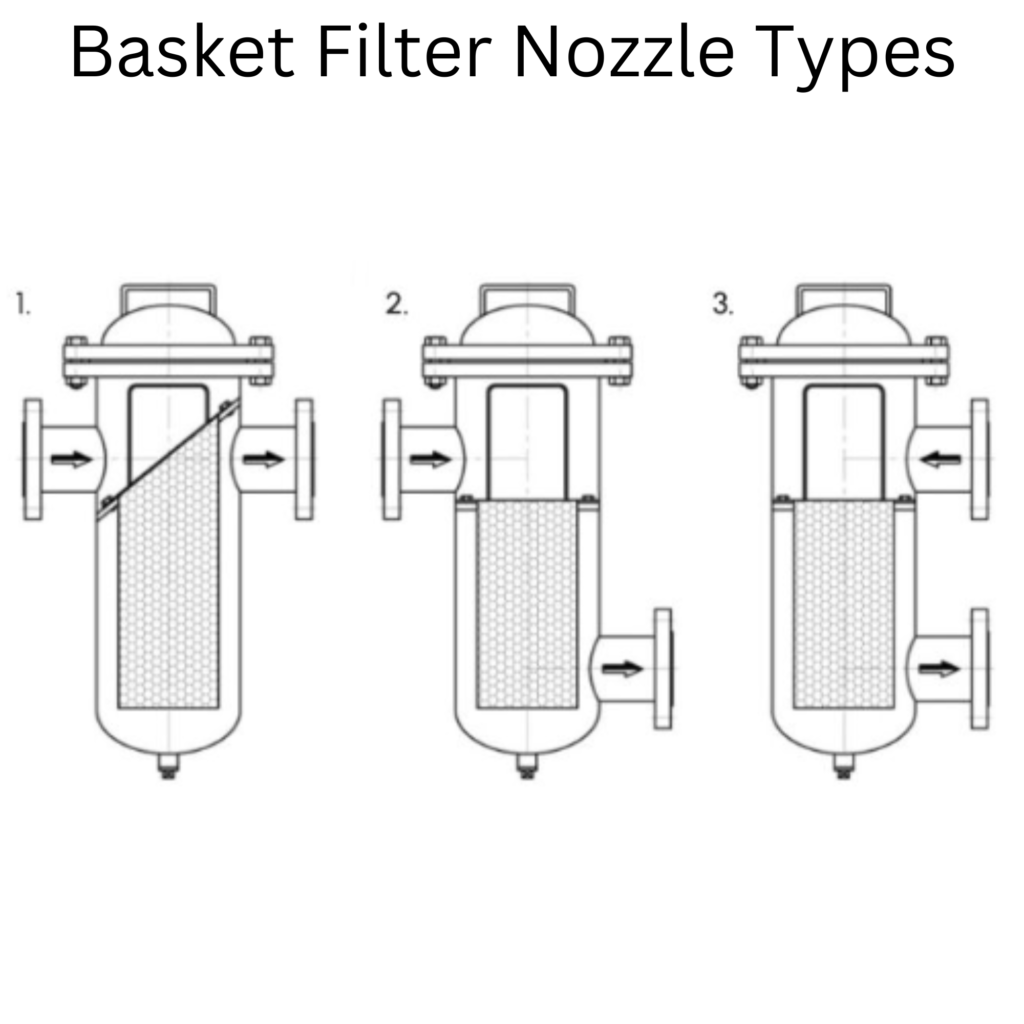

- Customization Options: Basket filters can be customized to meet specific process requirements. They can be tailored in terms of size, materials of construction, connections, and mounting options, ensuring optimal integration into the process system.

- Cost-Effective Solution: Basket filters offer a cost-effective filtration solution due to their efficient particle removal, long service life, and low maintenance requirements. They help extend the lifespan of downstream equipment and reduce the need for repairs or replacements.

Overall, the benefits and silent features of Basket Filters make them a reliable and effective choice for solid particle removal in process industries, contributing to improved process efficiency, equipment protection, and product quality.

Materials of Constructions (MOC):

- SA515 Gr.60

- SA516 Gr. 70

- IS2002

- IS2062,

- A106/ A53/IS1239/3589/ A105,

- ASTM A240 TP304

- ASTM A240 TP304-L

- ASTM A240 TP316

- ASTM A240 TP316-L

- A385/335/ A312TP 304/316

- A182/ F304 / 316/ F69 / F22/ F11

Applications:

- Oil and Gas Industry: Basket filters are used in oil and gas production, refining, and transportation processes. They are employed to remove contaminants, sediments, rust, and other solid particles from crude oil, natural gas, and refined products to protect downstream equipment and ensure product quality.

- Chemical Processing: Basket filters are essential in chemical plants to filter process fluids, including solvents, chemicals, and intermediate products. They help remove impurities, particulates, and solids that can cause equipment damage or affect the purity of the end products.

- Water Treatment: Basket filters play a crucial role in water treatment processes, including potable water production, wastewater treatment, and industrial water treatment. They are used to remove suspended solids, sediment, algae, and other particulate matter from water, ensuring clean and clear water for various applications.

- Pharmaceuticals and Biotechnology: Basket filters are employed in pharmaceutical and biotech industries to ensure the purity of process fluids, including pharmaceutical ingredients, drug formulations, and bioprocessing solutions. They help eliminate contaminants and particulates that can compromise product quality, sterility, and patient safety.

- Food and Beverage: In the food and beverage industry, basket filters are used to remove solid particles, debris, and impurities from liquids such as juices, syrups, cooking oils, and beverages. They help maintain product quality, prolong the shelf life of products, and prevent clogging in equipment like pumps and spray nozzles.

- Pulp and Paper: Basket filters are utilized in the pulp and paper industry for filtration applications involving various process fluids, including pulp slurries, chemical solutions, and water. They help remove fibers, contaminants, and solids to maintain the quality of paper products and protect equipment like pumps and nozzles.

- Petrochemical Industry: Basket filters are used in petrochemical plants for filtration in processes such as polymer production, fuel manufacturing, and chemical processing. They help remove solids, rust, and particulates that can cause equipment fouling, blockages, and inefficiencies.

- Power Generation: Basket filters find application in power plants, particularly in cooling water systems and fuel handling processes. They help remove debris, sediments, and contaminants from cooling water, condensate, and fuel oil, ensuring the efficient operation of turbines, boilers, and heat exchangers.

- Automotive and Manufacturing: Basket filters are used in various manufacturing industries, including automotive, metalworking, and machining. They are employed to remove chips, debris, and particulates generated during machining operations, protecting sensitive components and equipment.

- Mining and Minerals: Basket filters are utilized in mining and mineral processing to separate solids from process liquids, such as slurry streams and wastewater. They help remove solids, sediment, and impurities, ensuring efficient separation, improved process performance, and environmental compliance.

T.E.A.M. offers Basket Filters ranging from 5 microns & above.

T.E.A.M. Offers the specific application and selection of Basket Filters depending on factors such as the nature of the fluid, particle size, flow rates, operating conditions, and desired filtration efficiency. For any type of information, please feel free to contact us.

Sales & Marketing:

Sales & Marketing:  Service Supports:

Service Supports:  Website:

Website: