Agitators technology

Side Entry Agitators

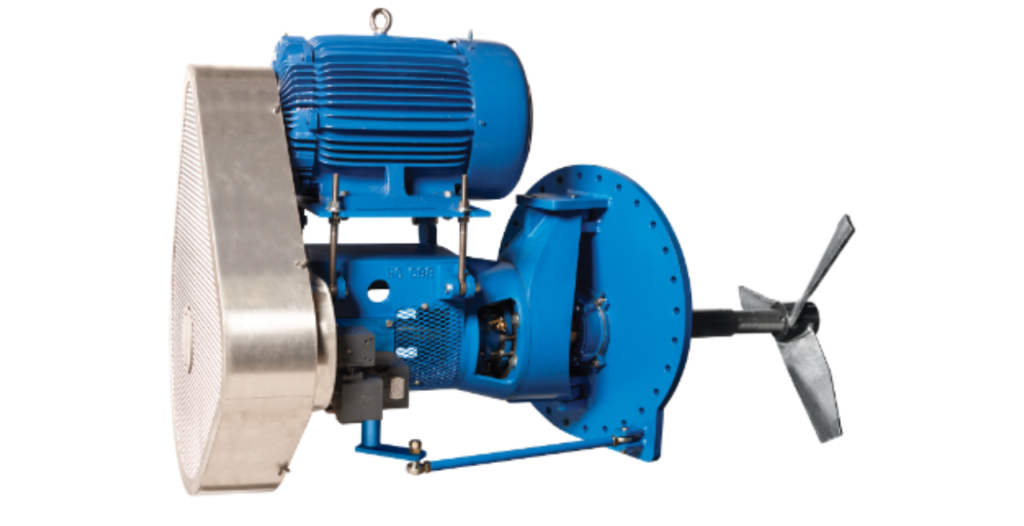

Side entry agitators, also known as side-mounted agitators or side entry mixers, are industrial mixing devices designed to agitate and homogenize liquids in tanks or vessels.

Unlike top entry agitators (mounted on the top of the tank) and bottom entry agitators (mounted on the bottom of the tank), side entry agitators are positioned on the side of the tank. The working principles of side entry agitators involve the following key aspects:

Design: A typical side entry agitator consists of an agitator shaft connected to a motor and impeller. The agitator is mounted on the side of the tank at a specific depth below the liquid’s surface.

Agitation: When the motor is activated, it drives the agitator shaft and impeller. The impeller’s rotation generates fluid motion, creating turbulence and promoting mixing within the tank.

Flow Patterns: Side entry agitators create flow patterns that vary depending on the impeller design and the specific application. These flow patterns facilitate blending and homogenization of the liquid contents.

Adjustable Depth: The depth at which the side entry agitator is installed in the tank can be adjusted to optimize mixing efficiency and reduce energy consumption.

Speed and Direction: The speed and direction of the impeller’s rotation can be adjusted to control the mixing intensity and direction.

Advantages:

Effective Mixing: Side entry agitators provide efficient mixing, ensuring uniformity and consistency of the liquid contents in large tanks.

Flexible Installation: These agitators can be installed at various depths within the tank, allowing customization for specific applications.

High Capacity: Side entry agitators are capable of handling large tank volumes, making them suitable for industrial-scale processes.

Energy Efficiency: They often require less power compared to some other mixing methods, resulting in energy savings.

Reduced Maintenance: Side entry agitators are generally reliable and require minimal maintenance when properly designed and maintained.

Disadvantages:

Initial Cost: The purchase and installation of side entry agitators can have higher upfront costs compared to some other mixing methods.

Space Requirements: The design of side entry agitators can limit the usable space along the tank’s side, which may be a constraint in some applications.

Applications: Side entry agitators are used in various industries and applications, including:

Petrochemical and refining: Mixing and blending of chemicals, crude oil, and petroleum products.

Water and wastewater treatment: Agitation and mixing in water treatment processes, including flocculation and chemical dosing.

Pulp and paper: Stirring and mixing pulp stock in paper manufacturing.

Chemical processing: Mixing chemicals, reagents, and polymers.

Food and beverage production: Blending ingredients in food and beverage processing.

Summary: Side entry agitators are versatile industrial mixing devices designed to efficiently agitate and homogenize liquids in tanks and vessels. They offer advantages such as effective mixing, flexibility in installation depth, high capacity, and energy efficiency. While they may have higher initial costs and space limitations, side entry agitators play a crucial role in achieving product consistency and quality in numerous applications across different industries.

Sales & Marketing:

Sales & Marketing:  Service Supports:

Service Supports:  Website:

Website: