Air Cooled/Finned Tubes Heat Exchangers are designed to transfer heat between a fluid (typically a process fluid or refrigerant) and the surrounding air.

They operate on the principle of forced convection heat transfer and employ finned tubes to enhance heat exchange.

The working principles of Air Cooled/Finned Tubes Heat Exchangers involve the following key aspects:

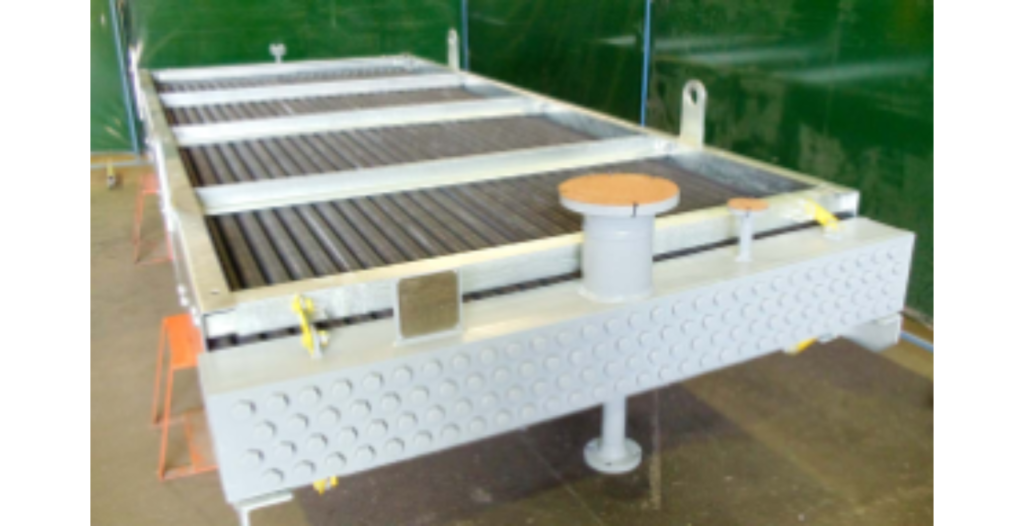

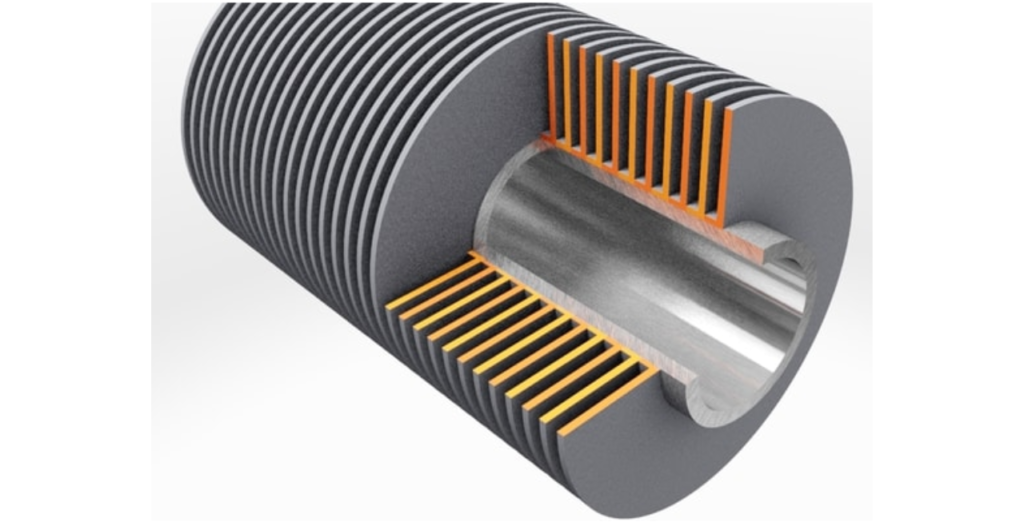

Design: Air Cooled/Finned Tubes Heat Exchangers consist of a bundle of finned tubes through which a hot or cold fluid flows.

These tubes are often arranged in rows and mounted within a framework. Large fans are installed on the framework to facilitate air circulation.

Heat Transfer: The fluid to be cooled or heated (process fluid) flows through the tubes, while air is blown over the finned surfaces by the fans.

Heat is transferred from the process fluid to the air (in the case of cooling) or from the air to the process fluid (in the case of heating) through the tube walls.

Fins: The fins on the outside of the tubes serve to increase the heat transfer surface area and enhance heat exchange efficiency. The increased surface area allows for improved heat dissipation into or from the surrounding air.

Airflow Control: The fans can be controlled to adjust the airflow rate, which affects the rate of heat transfer.

The process fluid’s temperature is adjusted by controlling the fan speed or air temperature.

Advantages:

Adaptability: Air Cooled/Finned Tubes Heat Exchangers are versatile and can be used for both heating and cooling applications across various industries.

Low Water Usage: They do not require water for cooling, making them suitable for locations with water scarcity or environmental restrictions.

Compact Design: Air Cooled/Finned Tubes Heat Exchangers have a relatively small footprint compared to other heat exchanger types, making them suitable for installations with limited space.

Low Maintenance: They have fewer components and are relatively easy to maintain compared to water-cooled heat exchangers.

Disadvantages:

Limited Cooling Capacity: Air Cooled/Finned Tubes Heat Exchangers may have limitations in terms of cooling capacity, especially in high-temperature applications.

Air Quality: The efficiency of Air Cooled/Finned Tubes Heat Exchangers can be affected by ambient air quality, such as dust and particulate matter, which may accumulate on the finned surfaces.

Applications: Air Cooled/Finned Tubes Heat Exchangers are used in a wide range of industrial applications, including:

Oil and gas processing: Cooling of hydrocarbons and process fluids.

Power generation: Cooling of steam condensers and turbine lube oil.

Chemical processing: Cooling of various chemical processes.

Refrigeration: Condensing refrigerant gases in air conditioning and refrigeration systems.

Petrochemical industry: Cooling of process streams and reactors.

Summary: Air Cooled/Finned Tubes Heat Exchangers are versatile devices used for transferring heat between a fluid and the surrounding air.

They operate based on forced convection heat transfer principles and use finned tubes to enhance heat exchange efficiency.

Air Cooled/Finned Tubes Heat Exchangers find applications in various industries for both cooling and heating purposes.

They are known for their adaptability, compact design, and low water usage.

However, their cooling capacity may be limited in high-temperature applications, and their efficiency can be affected by ambient air quality.

Overall, Air Cooled/Finned Tubes Heat Exchangers are valuable tools in industrial processes where efficient heat transfer is essential.