Textile Technology/Products

H.T.H.P. Horizontal Single Vessel Dyeing Plant

H.T.H.P. Horizontal Single Vessel Dyeing Plant is an industrial textile dyeing machine used for dyeing a variety of fabrics, Fibers, and yarns under controlled conditions of temperature and pressure.

This type of dyeing equipment is commonly used in the textile and garment industry. The working principles of an H.T.H.P. Horizontal Single Vessel Dyeing Plant involve the following key aspects:

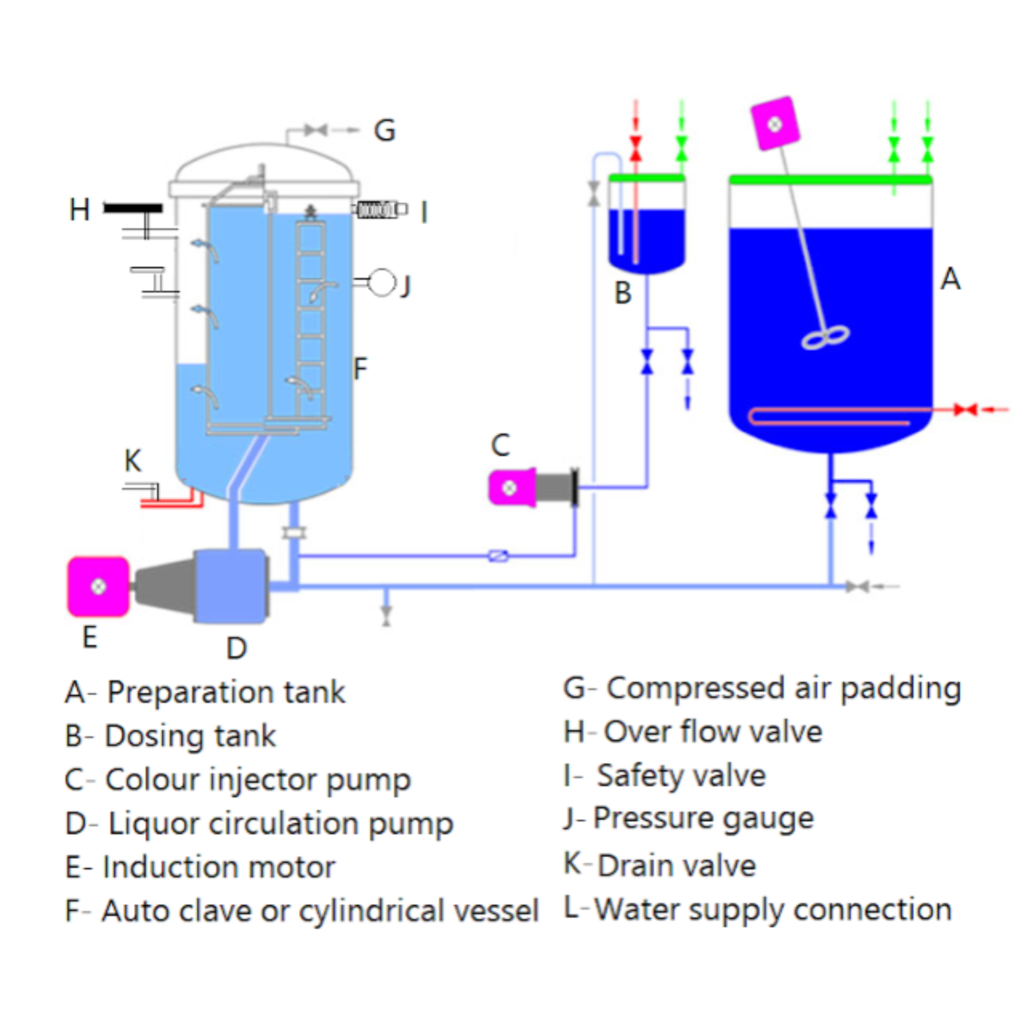

Design: The plant consists of a horizontal cylindrical vessel or chamber designed to accommodate a specific quantity of fabric or yarn. The vessel is typically made of stainless steel or other corrosion-resistant materials.

Dye Bath: The textile material to be dyed is loaded into the vessel along with the dye liquor, which contains the dye stuff, chemicals, and water.

Pressurization: The vessel is sealed, and a pressurization system is employed to increase the pressure within the vessel. This is typically achieved using a hydraulic or pneumatic system.

Heating: The dye bath is heated to the desired temperature using steam or electric heating elements. The combination of high temperature and pressure ensures the efficient and uniform dyeing of the textile material.

Agitation: Agitation mechanisms, such as paddles or rotary arms, are used to ensure that the textile material is evenly exposed to the dye liquor. Agitation helps in achieving uniform dye penetration and color consistency.

Dyeing Process: The textile material remains in the dye bath for a specified duration, allowing the dye to permeate the fibers or fabric. The temperature, pressure, and agitation are carefully controlled to ensure consistent and high-quality dyeing.

Cooling and Drainage: After the dyeing process is complete, the vessel is gradually depressurized, and the dye bath is cooled. The dyed material is then drained, rinsed, and subjected to post-treatment processes as needed.

Advantages:

Uniform Dyeing: H.T.H.P. Horizontal Single Vessel Dyeing Plants ensure uniform and consistent dye penetration, resulting in high-quality, evenly dyed textiles.

Time Efficiency: The combination of high temperature and pressure allows for faster dyeing cycles compared to conventional dyeing methods.

Reduced Water Consumption: These plants are designed to be water-efficient, minimizing water usage and wastewater generation.

Flexibility: They can be used for dyeing a wide range of fabrics, fibers, and yarns, making them versatile for different textile applications.

Energy Efficiency: Many modern systems are designed for energy efficiency, reducing operational costs.

Disadvantages:

Capital Investment: The initial cost of purchasing and installing H.T.H.P. Horizontal Single Vessel Dyeing Plants can be significant.

Maintenance: Regular maintenance is required to ensure the proper functioning of the equipment.

Environmental Impact: While these plants are designed to be water-efficient, they still generate wastewater that may require treatment and disposal.

Applications: H.T.H.P. Horizontal Single Vessel Dyeing Plants are widely used in the textile and garment industry for dyeing various materials, including cotton, polyester, silk, wool, and blends. They are suitable for applications such as:

Dyeing of fabrics for apparel and home textiles.

Dyeing of yarns for knitting and weaving.

Dyeing of technical textiles for industrial and specialized applications.

Dyeing of garments and finished textile products.

Summary: H.T.H.P. Horizontal Single Vessel Dyeing Plants are industrial textile dyeing machines designed for the uniform and efficient dyeing of fabrics, fibers, and yarns.

They operate under controlled conditions of high temperature and pressure, ensuring consistent and high-quality dyeing results. While they offer advantages such as uniform dyeing and reduced water consumption, they come with initial capital costs and maintenance requirements.

These plants play a crucial role in the textile industry by providing efficient and versatile dyeing solutions.

Sales & Marketing:

Sales & Marketing:  Service Supports:

Service Supports:  Website:

Website: