SYSTEM COMPONENTS & ACCESSORIES

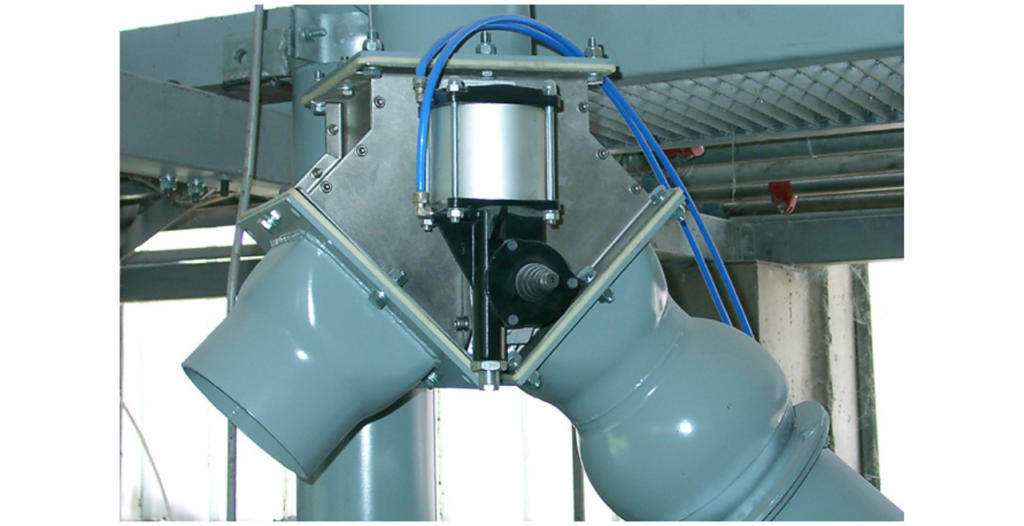

Diverter Valve

Diverter valve is a specialized type of valve used in various industries to redirect the flow of materials or fluids from one pathway to another.

It plays a crucial role in controlling the direction of flow within a pipeline or conveyor system.

Below is an overview of diverter valves, including their working process, advantages, disadvantages, applications, materials of construction (MOC), and a summary:

Working Process:

Diverter valves operate by changing the direction of flow within a pipeline or conveyor system.

They typically have multiple inlet and outlet ports and a mechanism that allows them to divert the flow from one inlet to one or more outlets, or vice versa.

The working process can be summarized as follows:

Normal Flow: In its default position, a diverter valve allows material or fluid to flow through one inlet and exit through one outlet.

Diverting Flow: When the valve is actuated or controlled, it redirects the flow, blocking the default outlet and allowing the material or fluid to exit through another outlet. The redirection can be done manually, pneumatically, electrically, or using other means, depending on the valve’s design.

Position Control: Diverter valves can have multiple positions or settings to control the direction and distribution of flow according to specific requirements.

Advantages:

Flow Control: Diverter valves provide precise control over the direction of material or fluid flow, making them valuable in systems where flow distribution is critical.

Reduced Cross-Contamination: In applications where different materials must be conveyed through the same pipeline, diverter valves help prevent cross-contamination by directing each material to the intended destination.

Flexibility: These valves can be integrated into various systems and processes, offering versatility in material handling and distribution.

Minimized Downtime: Diverter valves enable quick and efficient switching between different process lines or equipment, reducing downtime.

Disadvantages:

Maintenance: Like all valves, diverter valves require regular maintenance to ensure proper functioning and prevent leakage.

Complexity: Some diverter valve designs can be complex, and their proper installation and operation may require expertise.

Pressure Loss: Depending on the design, diverter valves may cause pressure drops in the system, affecting efficiency.

Applications: Diverter valves are used in a wide range of industries and applications, including:

- Agriculture: In grain handling and seed processing systems.

- Food Processing: For diverting food products between processing lines.

- Chemical Processing: In chemical manufacturing and distribution processes.

- Pharmaceuticals: For routing pharmaceutical powders and granules.

- Mining: In mineral processing and material handling.

Materials of Construction (MOC): The choice of materials for diverter valves depends on the type of materials or fluids being handled and the operating conditions. Common materials of construction include:

- Valve Body: Stainless steel, carbon steel, cast iron, aluminum, or specialized alloys.

- Seals: Elastomers such as EPDM, Viton, or PTFE, chosen based on chemical compatibility.

- Internal Components: Material selection may vary depending on the valve design and its intended use.

Summary:

Diverter valves are essential components in industries where precise control over the direction of material or fluid flow is critical.

They offer advantages such as flow control, reduced cross-contamination, flexibility, and minimized downtime.

However, they require regular maintenance and can be complex in design. Diverter valves find applications in agriculture, food processing, chemicals, pharmaceuticals, and mining, and their materials of construction are chosen based on the specific needs of the application.

Sales & Marketing:

Sales & Marketing:  Service Supports:

Service Supports:  Website:

Website: