RAW MATERIALS HANDLING SYSTEMS & CONVEYING TECHNOLOGY & PRODUCTS

BULK SOLID CONVEYING AND GRAIN HANDLING SYSTEMS

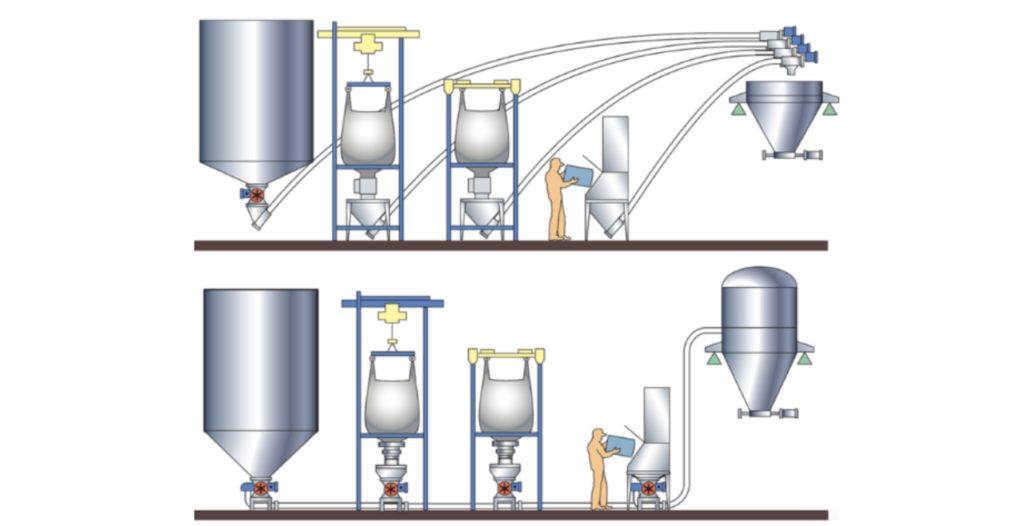

Bulk solid conveying and grain handling systems are integral components within process industries that facilitate the efficient movement and transportation of bulk solid materials, including grains, powders, granules, and other particulate matter.

These systems play a crucial role in various industries, such as agriculture, food processing, pharmaceuticals, mining, and manufacturing.

Bulk Solid Conveying Systems:

Definition: Bulk solid conveying systems are equipment and mechanisms designed to transport large quantities of dry, granular, or powdered materials from one location to another within a production or processing facility.

Components: Bulk solid conveying systems consist of several key components, including conveyors (e.g., belt conveyors, screw conveyors, pneumatic conveyors), hoppers, chutes, feeders, and storage silos or bins. These components work together to move materials efficiently.

Types of Conveyors: Different types of conveyors are chosen based on the specific characteristics of the bulk solid being handled. For example, belt conveyors are ideal for moving large volumes of material, while pneumatic conveyors use air pressure to transport finer materials.

Automation: Automation is commonly used in bulk solid conveying systems to control the flow of materials, optimize routing, and monitor the process. PLCs (Programmable Logic Controllers) and sensors play a crucial role in ensuring efficient operation.

Industries: These systems find applications in industries such as agriculture (for moving grains and seeds), mining (for transporting ores and minerals), manufacturing (for handling raw materials), and construction (for conveying cement and aggregates).

Grain Handling Systems:

Definition: Grain handling systems are a specific subset of bulk solid conveying systems designed for the storage, transportation, and processing of grains and cereals, such as wheat, corn, rice, and barley.

Components: Grain handling systems include grain elevators, storage silos, conveyors, bucket elevators, and grain dryers. These components are optimized for the unique characteristics of grains, including their size, weight, and moisture content.

Automation: Automation in grain handling systems is essential for precise control of moisture levels, temperature, and grain flow. It helps prevent spoilage, ensure quality, and optimize storage.

Challenges: Grain handling systems face specific challenges related to grain quality preservation, pest control, and maintaining suitable storage conditions. Efficient aeration and temperature monitoring systems are used to address these issues.

Safety: Grain handling can be hazardous due to the risk of grain engulfment and grain dust explosions. Safety measures, including proper ventilation and safety equipment, are essential to protect workers.

Industries: Grain handling systems are primarily used in the agriculture and food processing industries, where the efficient and safe handling of grains is critical for food production.

If You Have Specific Inquiries About Mixers And Blenders Or Require Design Services, Please Contact Our Sales Team @ T.E.A.M. Engineer’s Multi-Equipment & Multi-Services Pvt. Ltd. As Soon As Possible

Sales & Marketing:

Sales & Marketing:  Service Supports:

Service Supports:  Website:

Website: