CONVEYORS

Screw Conveyors

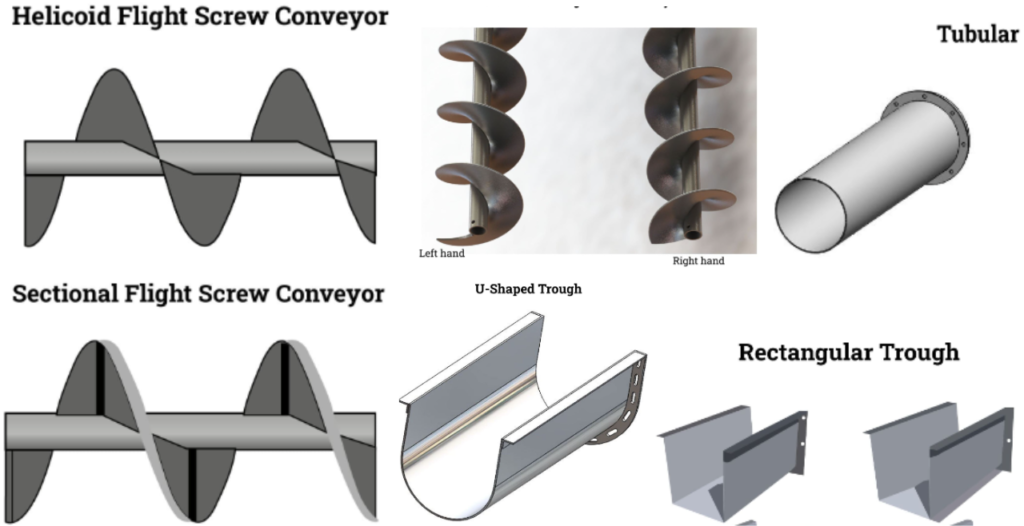

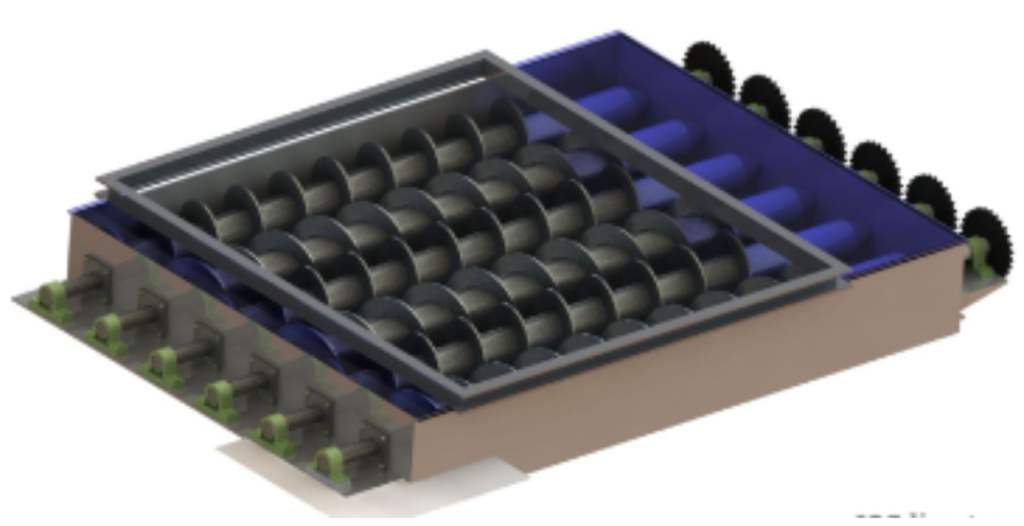

Screw conveyors, also known as auger conveyors, are mechanical conveying systems designed to move bulk materials horizontally or at a slight incline using a rotating, helical screw. The working principles of screw conveyors involve the following key aspects: |

| Rotation: A helical screw, also known as an auger, is enclosed within a cylindrical casing or trough. When the screw rotates, it creates a continuous, spiral flow path inside the casing. |

| Material Movement: As the screw rotates, it pushes material forward along the conveyor’s length. The material moves in the direction of the screw’s rotation. |

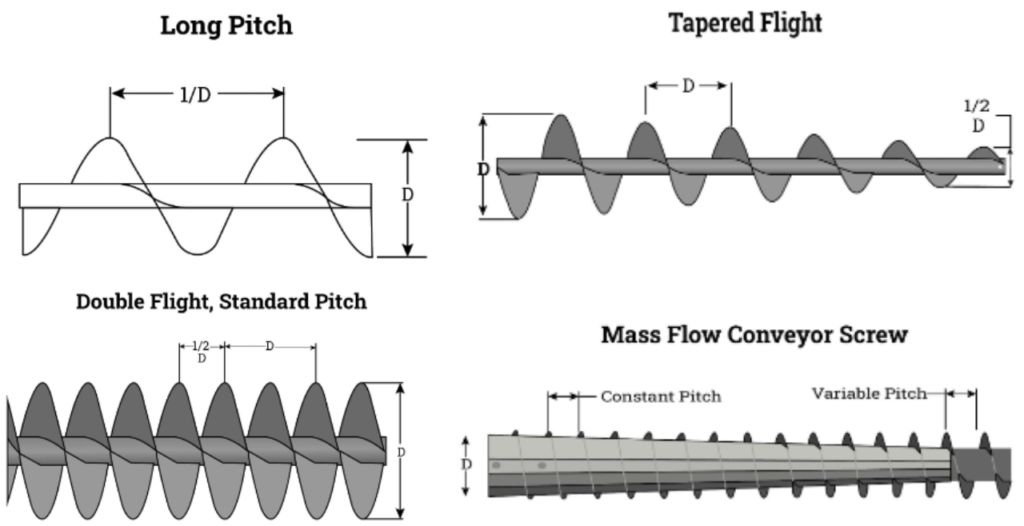

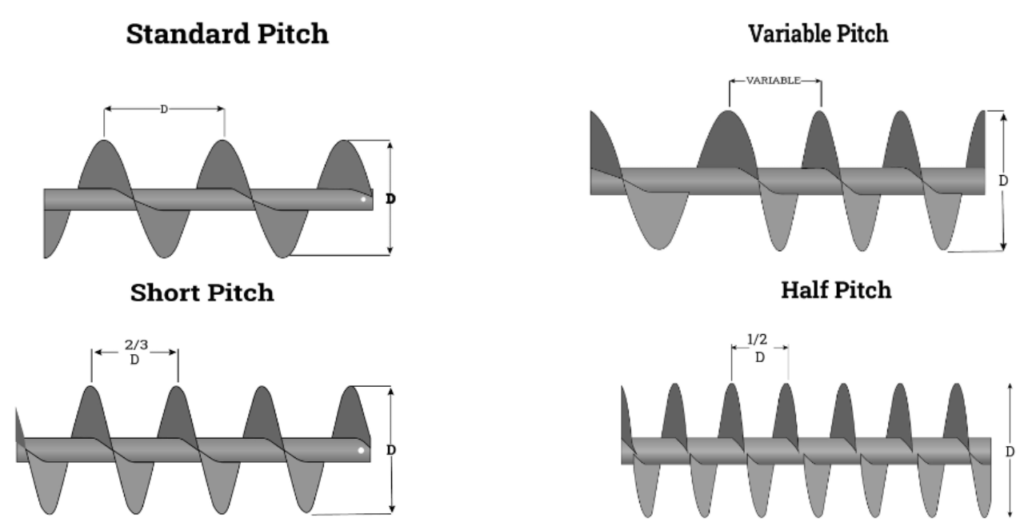

| Inlet and Outlet: Material is typically fed into the conveyor at the inlet, and it is discharged at the outlet. The rate of material movement is controlled by the screw’s rotation speed and the pitch of the helix. |

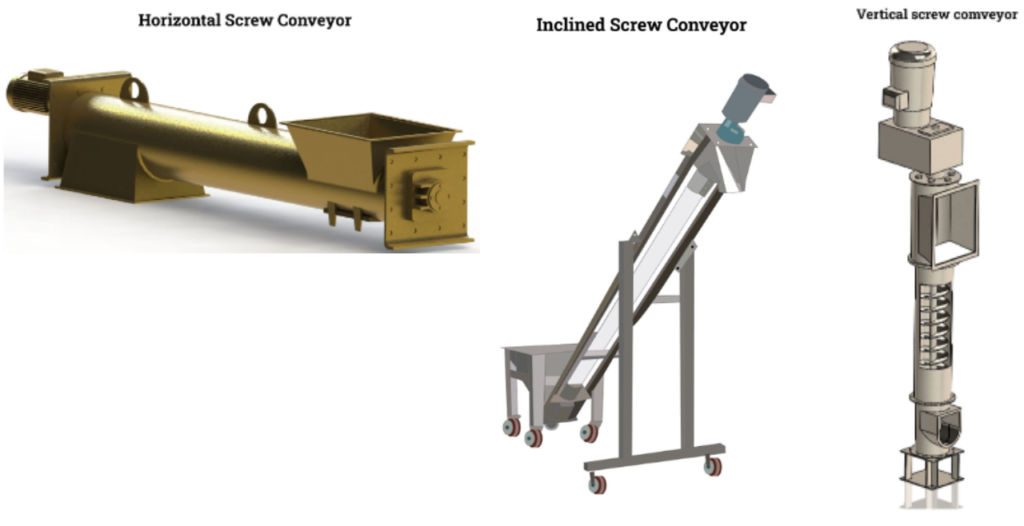

| Variable Configurations: Screw conveyors come in various configurations, including horizontal, inclined, and vertical designs. They can also have multiple sections to change the material’s direction or elevation. |

| Advantages: |

| Versatility: Screw conveyors can handle a wide range of bulk materials, including powders, granules, flakes, and liquids, making them suitable for diverse industries. |

| Gentle Material Handling: Screw conveyors provide gentle material handling, reducing the risk of product degradation or damage during transport. |

| Simple Design: Screw conveyors have a relatively simple design, resulting in ease of maintenance and cost-effectiveness. |

| High Throughput: They can handle high throughput rates, making them suitable for applications requiring continuous material transfer. |

| Customizable: Screw conveyors can be customized in terms of length, diameter, and materials of construction to meet specific application requirements. |

| Disadvantages: |

| Limited Incline: Screw conveyors are generally suitable for low to moderate inclines. For steep inclines, other conveyor types may be more appropriate. |

| Material Compatibility: Some materials may be abrasive or corrosive, requiring specialized materials of construction or protective coatings. |

| Applications: |

| Screw conveyors find applications in various industries, including: |

| Agriculture: Transporting grains, seeds, and feed. |

| Food and Beverage: Conveying bulk ingredients, such as flour, sugar, and spices. |

| Chemical and Pharmaceutical: Handling bulk chemicals, powders, and granules. |

| Mining and Minerals: Moving minerals, ores, and aggregates. |

| Wastewater Treatment: Removing and transporting dewatered sludge. |

| Construction: Transporting cement, sand, and other construction materials. |

| Environmental Engineering: Handling biosolids and waste materials. |

| Manufacturing: Conveying raw materials and components. |

Summary:

Screw conveyors are versatile mechanical conveying systems that use a rotating helical screw to move bulk materials horizontally or at a slight incline. They provide gentle material handling, have a simple design, and can handle a wide range of materials. Screw conveyors are used in diverse industries, including agriculture, food and beverage, chemicals, and construction, among others, for efficient and continuous material transport. Proper selection and design of screw conveyors are crucial to ensure their effectiveness and reliability in specific applications.

Sales & Marketing:

Sales & Marketing:  Service Supports:

Service Supports:  Website:

Website: