Pharmaceutical Technology/Products

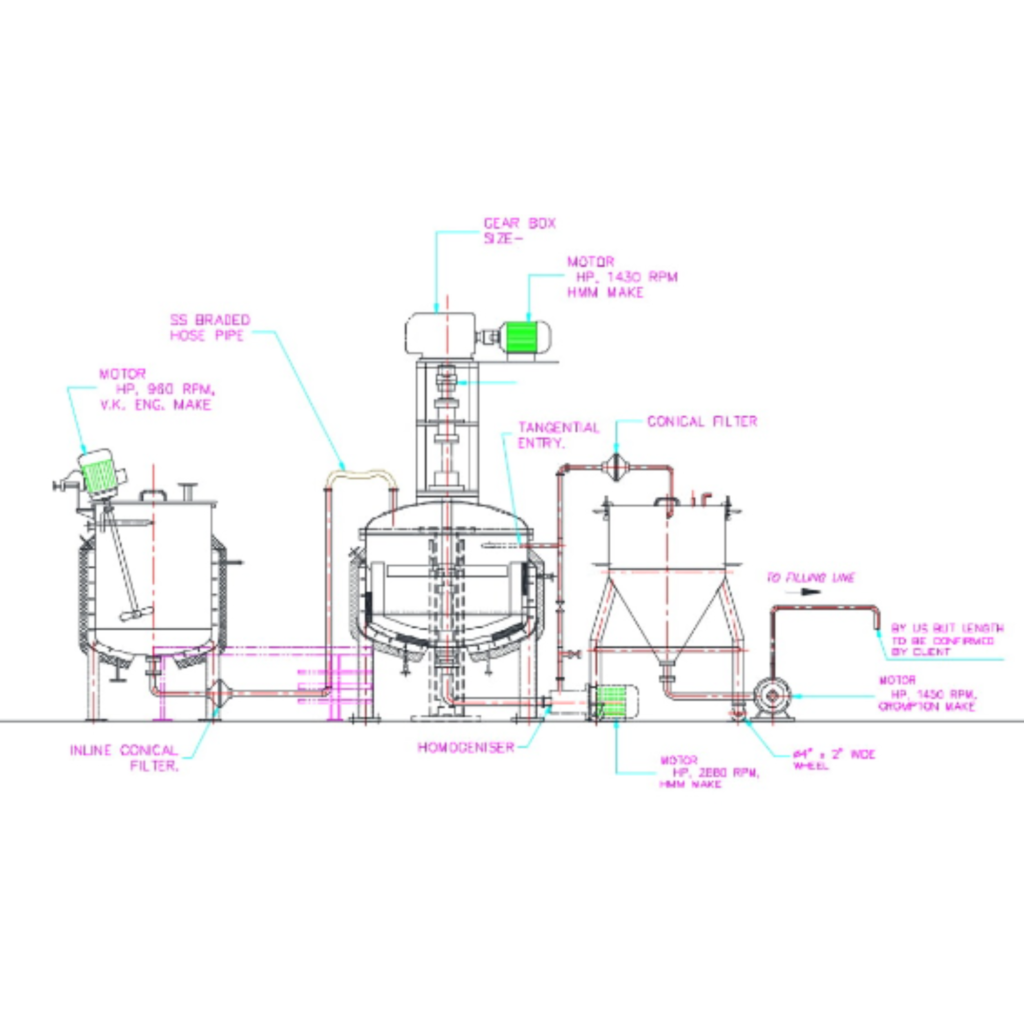

Ointment Manufacturing Plant

Working Principles: An Ointment & Cream Manufacturing Plant is a specialised facility used in the pharmaceutical and cosmetic industries for the production of ointments, creams, gels, and other semi-solid products.

The manufacturing process involves several key steps:

Preparation of Ingredients: Raw materials such as active pharmaceutical ingredients (APIs), excipients, emulsifiers, and stabilizers are accurately weighed and mixed in the required proportions to create the formulation.

Heating and Melting: Some ingredients, like waxes and fats, are heated and melted to create a homogeneous blend. This is typically done in a separate vessel or jacketed tank.

Mixing and Homogenization: The melted ingredients are mixed and homogenized to ensure uniform distribution of the components. High-shear mixers or homogenizers may be used for this purpose.

Cooling: The mixture is then cooled to a temperature suitable for the addition of heat-sensitive ingredients, such as preservatives and fragrances.

Addition of Heat-Sensitive Ingredients: Heat-sensitive ingredients are added to the mixture under gentle mixing conditions.

Emulsification: In the case of emulsion-based formulations (e.g., creams), oil and water phases are emulsified together to create a stable product.

Filling and Packaging: The final product is filled into containers, such as tubes, jars, or bottles, and then sealed.

Quality Control: Quality control measures are implemented throughout the process to ensure product uniformity, stability, and safety.

Advantages:

Customization: Ointment and cream manufacturing plants allow for the customization of formulations to meet specific requirements, including texture, viscosity, and active ingredient concentration.

Efficiency: Modern manufacturing plants use automated and controlled processes, ensuring efficient and consistent production.

Quality Control: Stringent quality control measures are implemented to produce safe and effective products.

Disadvantages:

Cost: Setting up a fully equipped ointment and cream manufacturing plant can be costly, particularly for small-scale manufacturers.

Regulatory Compliance: Strict regulatory requirements, especially in the pharmaceutical industry, must be adhered to, which can be challenging and time-consuming.

Applications: Ointment and cream manufacturing plants are primarily used in the pharmaceutical and cosmetic industries for the production of various topical products, including:

Pharmaceutical ointments and creams for skin conditions and medical applications.

Cosmetic creams, lotions, and gels for skincare and beauty products.

Veterinary ointments and creams for animal health.

Summary: An Ointment & Cream Manufacturing Plant is a specialized facility used for the production of ointments, creams, and semi-solid products.

The process involves the precise preparation of ingredients, mixing, emulsification (for creams), cooling, and quality control.

These plants offer customization, efficiency, and stringent quality control, making them essential for pharmaceutical and cosmetic manufacturers.

However, they require a significant initial investment and must comply with strict regulatory standards

Sales & Marketing:

Sales & Marketing:  Service Supports:

Service Supports:  Website:

Website: