Nauta Mixers:

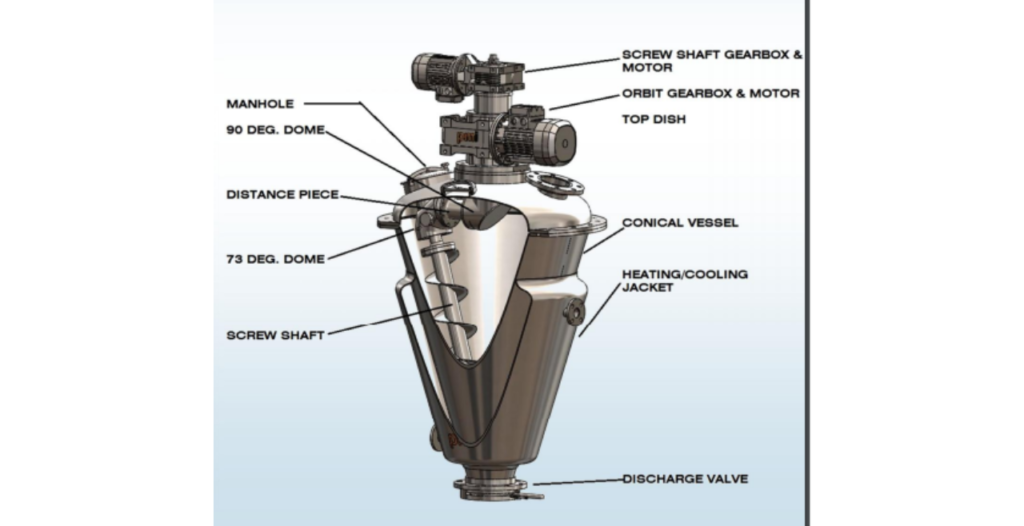

Nauta mixer, also known as a conical screw mixer, is a specialized blending and mixing device used in various industries to homogenize dry powders, granules, and other solid materials.

It is known for its unique conical shape and screw design, which facilitate efficient and gentle mixing.

Here’s an overview of its working principles, advantages, and disadvantages:

| Working Principle: The Nauta mixer operates on the principle of convective mixing, which involves the movement of materials within the mixer due to the combination of gravity and the action of the mixing screw. The key working principles include: |

| Conical Geometry: The Nauta mixer consists of a conical vessel with a helical screw or ribbon that runs along the inner surface of the cone. The screw is mounted on a central shaft that rotates. |

| Loading: The dry materials to be blended are loaded into the mixer through an opening at the top. |

| Blending: As the central screw rotates, it gently lifts and moves the materials upward along the inner surface of the cone. This lifting action causes the materials to cascade and flow back down to the bottom, creating a continuous blending motion. |

| Mixing: The materials flow along the spiral path created by the screw, ensuring thorough mixing as they move from the bottom to the top of the conical vessel. The gentle blending action minimizes the risk of product degradation, making it suitable for sensitive or fragile materials. |

| Discharging: Once the blending process is complete, the blended mixture can be discharged through an outlet at the bottom of the conical vessel. |

| Advantages of Nauta Mixers: |

| Uniform Mixing: Nauta mixers offer excellent mixing uniformity, ensuring that all components are evenly distributed throughout the mixture. |

| Gentle Mixing: The mixing action is gentle on sensitive or fragile materials, reducing the risk of product degradation. |

| Versatility: Nauta mixers can handle a wide range of materials, including powders, granules, and materials with varying particle sizes. |

| Customization: The design and configuration of the screw can be tailored to meet specific blending requirements, making them suitable for various applications. |

| Ease of Cleaning: Many Nauta mixers are designed for easy cleaning and sanitation, which is essential for industries with strict hygiene requirements. |

| Disadvantages of Nauta Mixers: |

| Batch Process: They are typically used for batch processing, which may not be ideal for continuous production lines. |

| Complex Design: The presence of the conical vessel and screw adds complexity to the mixer’s design, which may require more maintenance over time. |

| Limited for Cohesive Materials: Nauta mixers may not be the best choice for highly cohesive or sticky materials that can adhere to the screw or cone. |

| Equipment Size: Large-scale Nauta mixers can require significant space and may not be practical for small production facilities. |

| Cost: The initial cost of Nauta mixers can be relatively high compared to simpler mixing equipment. |

In summary, Nauta mixers are efficient and versatile mixing devices used in various industries to achieve uniform blending while minimizing the risk of product degradation.

Their unique conical design and screw configuration make them suitable for a wide range of materials, but they may have limitations with highly cohesive materials and are generally used for batch processing.

The choice of mixer type should be based on the specific characteristics of the materials and the blending requirements of the process.

Sales & Marketing:

Sales & Marketing:  Service Supports:

Service Supports:  Website:

Website: